Understanding Blind and Buried Vias

Vias in the printed circuit board ensure proper electrical connections between board layers. Although the board has standard through-hole vias, the most advanced ones are buried and blind vias. So, how do these vias differ from each other? How should you fabricate blind and buried vias for PCB? Find the details about the vias before designing your PCB board.

How Does a Blind Via Differ From A Buried Via?

Vias refer to interlayer connections that have special capabilities. They are intended to create a conductive path between layers in a PCB configuration. The usage of blind and buried vias leads to the miniature of electronic products.

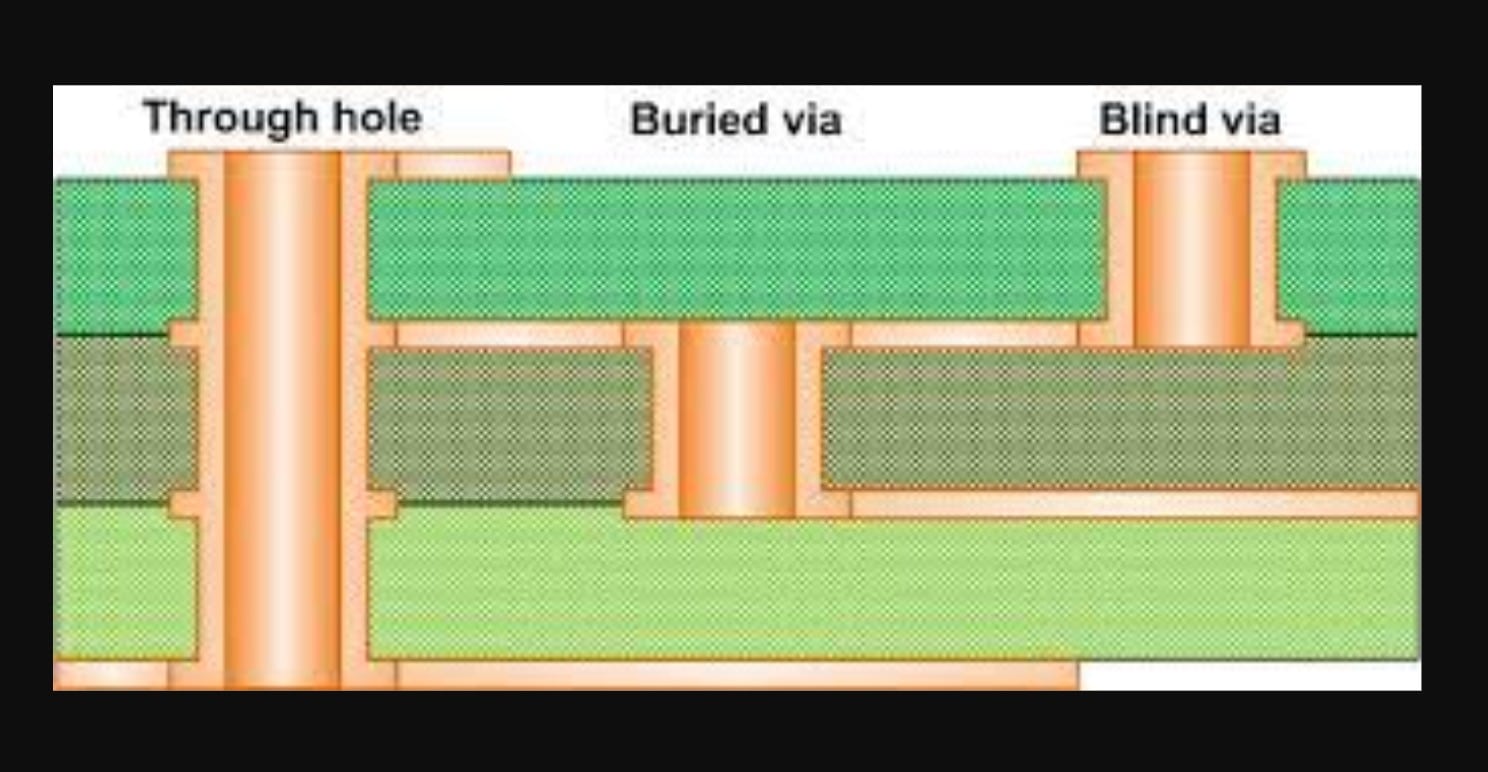

If you want to establish connections between 2 outer layers and inner layers, you can use the blind vias. But, it does not pass across the thickness of the board. It is only capable of traversing different layers. The blind via is visible only from the bottom or top surface. On the other hand, a buried via deal with inter layers for interconnections. It is not identifiable from the surface of the circuit board.

Defining Blind and Buried Vias

Before understanding the differences, you should learn about blind and buried vias.

A blind via refers to the drilled hole connecting the external PCB layers to multiple internal layers. However, it does not cover the overall board. You can view the vias from one side of your PCB board. That is why these vias are known as blind PCB vias. The application of these vias is mainly in high-density PCBs because engineers will need more circuitry on a single board.

The blind PCB vias are also effective in directing signals to the inner layers from the surface ones. Thus, the signal routing process will become highly efficient. Moreover, the blind via lets you minimize the drilling needs and manufacturing costs.

If the PCB vias connect multiple internal layers, you can consider them buried vias. They do not cover the exterior board layers. You cannot view them from the outside, and so they are referred to as buried vias.

Especially multilayer PCBs have buried vias because you need to connect a series of internal layers. With the buried vias, you can avoid using a large number of through-hole vias. So, they ensure reduced interference risks and better signal integrity. Besides, if you want to make the best use of space in your PCB designing project, a buried via is the right choice.

Advantages of Using Blind And Buried Vias–

A buried via is advantageous because it-

Saves your space- With the buried via, you will be able to save space where you can use layers for routing signal traces.

Reduces signal length– High-speed circuits need the buried vias to decrease the length of the signal trace. Thus, they will prevent noise, crosstalk, and other issues on your board. You will have no problem with signal integrity.

Better thermal management- The buried PCB vias are efficient at making thermal effects. Engineers can use the vias for places that generate a high amount of heat. The heat moving to a different circuit layer will spread at a fast rate. With the buried PCB via, the board will perform better under harsh thermal environments.

Highly reliable– As the buried PCB via has no connection with the external environment. Thus, the via has no effect from moisture and dust. The buried via’s quality is better than that of the blind PCB via.

A Blind PCB Via Benefits You In Different Ways–

A hassle-free manufacturing- Designing a blind PCB via is comparatively easy. You will be able to drill the via by drilling the through holes. But, you should take accurate measurements for designing the vias. It will help you avoid too shallow or deep drilling.

Ideal for SMT components- SMT components on the bottom and top layers of your PCB circuit board are easy to connect with the blind PCB vias.

An affordable choice- If you compare the manufacturing cost of both blind and buried vias, you will find the former more affordable.

Known for excellent reliability- A blind PCB via passes through a small part of your PCB. The consistency of your board will have no adverse effect because the PCB via does not fully move across the board. It leads to a reduced chance of mechanical errors, such as manufacturing issues and drill breakouts.

Choose The Best PCB Manufacturers–

It is important to look for a trusted manufacturer who ensures proper placement of blind and buried vias. The best manufacturers know how to meet your needs by designing the PCB board flawlessly. They have an advanced and well-equipped manufacturing facility that manages sophisticated processes and equipment. The goal of a PCB manufacturer should be to provide consistency and quality. So, make your deal with the PCB manufacturing company and get a high-quality product.

How Should You Fabricate Blind And Buried Vias?

Manufacturing a PCB is a complicated process. You need to design the blind and buried vias while fabricating the board. Some manufacturers use a rivet gun and a 2-layer board to make the vias.

Vias present a path for transferring thermal and electrical energy between different board layers. With the dissipation of more energy, it has to connect more vias with the thermal pad. So, let us now talk about the process of designing PCB and vias.

A PCB fabrication project involves converting layouts developed on a computer into a circuit board. Engineers need to produce a smooth-performing circuit board with the process. PCBs are of different types, such as double, single, and multilayer.

If you want a multilayer PCB, fabricators will print every layer on the sheet using a UV printer. The printed layers are known as blueprints, which are convertible into laminates. Manufacturers have to cure them under UV rays to make PVB tracks harder. Wash the laminates with alkaline solutions and dissolve the rest of the copper.

After printing and etching the outer and inner layers, the boards can be aligned properly. Then, the bottom and top layers need etching.

During this board fabrication process, engineers will drill the vias depending on your needs. They will start drilling the blind via after making the stack. But manufacturers will prepare it before stacking if you need a buried via. This is because after stacking the laminates together, they will not be able to drill holes in layers. There is no need to leave a track on the bottom or toy layers.

The process for designing blind and buried vias involves a large number of steps. In the case of a standard via manufacturing process, you may need to undergo only fewer steps.

The biggest challenge for manufacturers is to ensure proper alignment of holes with the layers. The conductive material will cover the hole without a gap.

Find The Most Reliable Manufacturers Of Blind And Buried Vias–

If you want to decide on the blind and buried vias size, you can contact the manufacturer to learn about the minimum size for the drill and annular ring. In the case of standard mechanical drills, the diameter is not less than 12 mil. The smallest vias size you can order has a hole with a diameter of 12 mil.