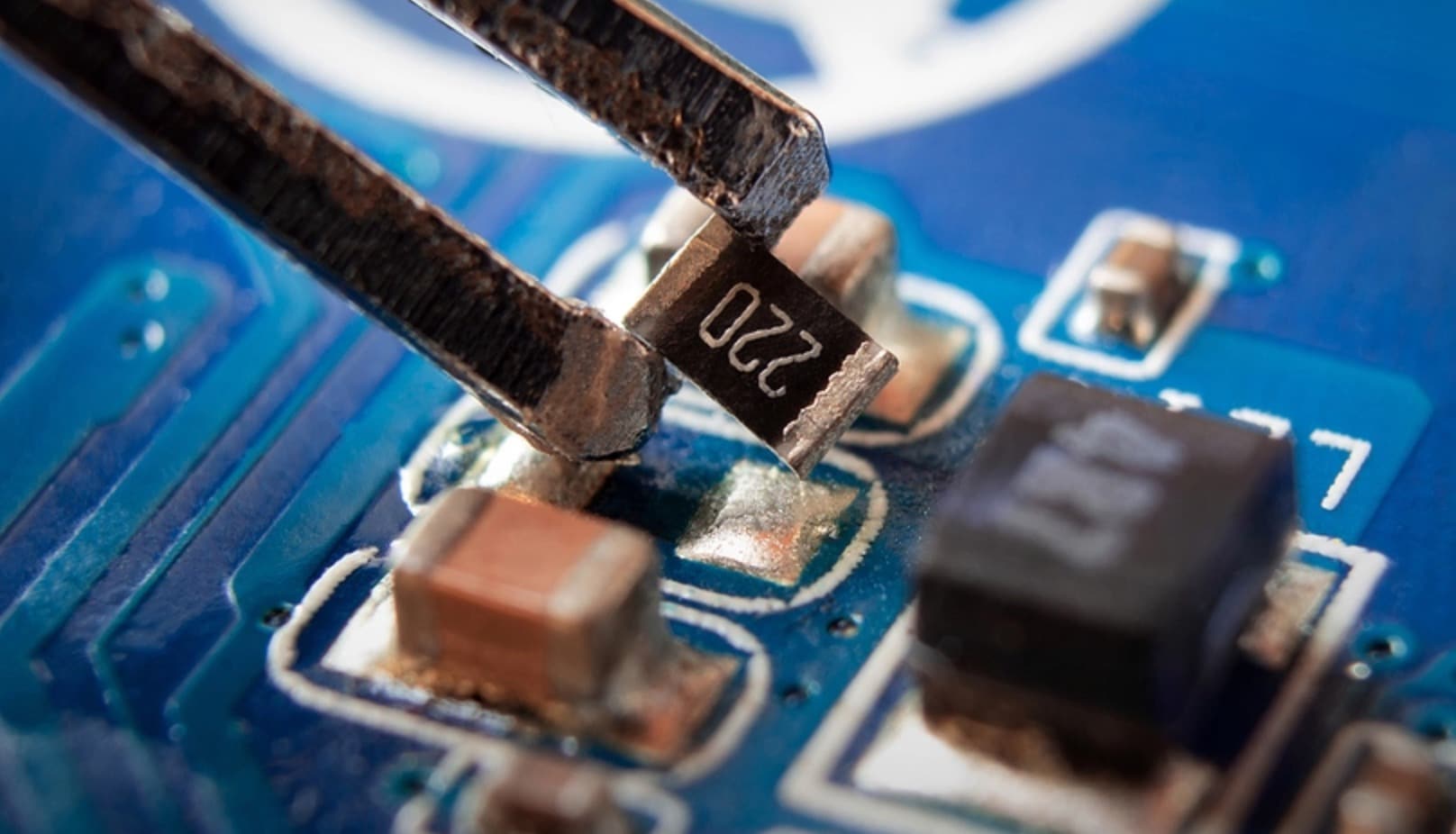

SMD Components :Types and Functionality

A type of electronic element known as surface-mounted devices (SMDs) or surface-mounted components are specifically designed to be surface-mounted on PCBs to manufacture electronic gadgets. SMD components are attached to the PCB substrate utilizing joining processes, for example, reflow oven soldering. Unlike conventional methods, these processes do not include leads or cables. SMD technologies are essential to contemporary electronics production for gadgets like cell phones, laptops, and other consumer goods. They allow for increased component concentration, reduced PCB dimensions, better electric efficiency, and automatic assembling procedures.

Types and Functionality

There are many types of SMD components, each serving a unique and distinctive purpose. These little parts collectively form the base upon which modern electronics are built. As such, ensuring their proper deployment on the PCB is critical. Understanding the various types and their specific function helps in knowing their best applications and employing best practices when handling them. The following is a comprehensive SMD component list and their unique functions.

- Resistor Component: Managing currents and voltage degrees requires the utilization of resistors, which restrict the movement of electrical energy within the circuit. SMD components like resistors and output ratings are available in varying degrees of resistance for various uses.

- Capacitor: A capacitor is another of the most common types of SMD components. It is useful for the storage and release of electrical power. In addition to balancing the electrical supply, they aid in noise reduction and voltage leveling. There are several types of capacitors, such as stable and reliable tantalum capacitors, high capacitance electrolytic capacitors, and ideal for high-frequency usage ceramic.

- Integrated Circuit Systems: ICs integrate many electronic SMD components, including capacitors, resistors, etc., on a single chip. In electrical equipment, they carry out several tasks, such as processing, signal manipulation, enhancement, and storing information in memory.

- Diodes: Diodes are a critical type of SMD part used in electronics. When two diodes are used, the electricity can move in one direction but not the other. They play a crucial role in voltage control, signal demodulation, and rectification of AC (alternating current) into DC (direct current).

- Transistor Components: In electrical networks, a transistor functions as a signaling regulator, router, or amplification device. They are vital parts of most electrical equipment and regulate the passage of voltages and electrical currents.

- Crystal Oscillator Components: The exact electrical impulses that crystal oscillator SMD components produce at particular wavelengths are essential for synchronizing and scheduling operations within microcontrollers, processing units, and digital electronics.

- Inductor Components: Whenever electrical current travels through inductive components, its energy is stored in an electrical field. These SMD components are crucial for energy conversions and signal analysis because they control current, filter off high-frequency vibration, and interpret signals.

- Thermal Resistors: Rising or falling temperatures cause thermal resistors to alter their resistance. These SMD components are employed in circuit safeguarding against overheating, thermal reimbursement, and temperature measurement systems.

- LED Components: Whenever an electrical current travels through Light-Emitting Diodes (LEDs), they generate light. Because of their extended longevity and energy savings, surface mount devices LEDs are commonly utilized in display panels, indication lights, and other lighting systems.

- Connections and Switches: SMD connectors and switches allow users to communicate with gadgets and create electrical links. These types of SMD components are frequently utilized in many electronic devices and help with the input and emission of electrical energy or impulses.

- Voltage Controllers: These SMD components constantly preserve the same resultant voltage value regardless of variations within the input voltages. These guarantee the steady supply of electrical voltages needed for delicate electronic parts.

- EMI filters and fuses: SMD fuses stop flowing electricity once electrical current reaches a particular threshold, protecting circuits against current overload. The effects of electromagnetic interference (EMI) and radiofrequency disturbances and interference are suppressed using EMI filters to preserve signal integrity.

- Advantages and Drawbacks of SMD Components

Advantages

- Reducing size: Due to the decrease in dimensions of SMD components, electronic items can be made more portable and lightweight. Because of their diminutive size, compact printed circuit boards may be designed for light electronics like smartwatches, mobile phones, and the Internet of Things.

- Increased Components Concentration: More SMD components can be easily placed on printed circuit boards because of SMD technologies. The general efficiency of electronic equipment is improved by this higher density, which enables greater versatility within less space.

- Enhanced Electrical Capability: Withinsurface mount components groups, more minor connector routes lead to lower parasitic capacitance and inductance, which improves electrical efficiency by reducing disturbance and signal degradation.

- Expense-effectiveness: The significant degree of automation in SMD production procedures lowers labor expenses and boosts output effectiveness. SMD part assemblage that utilizes automation cuts turnaround time, reducing huge-scale production expenses.

- Increased Pace and Efficiency: SMD components are manufactured quicker than traditional assembling processes. Machines may swiftly place several parts simultaneously, improving productivity and manufacturing speeds.

- Suitability for Cutting-Edge Technologies: Because SMD componentscan handle smaller parts and integrated networks, they can satisfy the needs of developing gadgets, allowing for adopting emerging innovations and technologies in electronic parts.

- Decreased Construction Material and Dimensions: Systems with smaller parts and diminished printed circuit boards are lighter, which is advantageous in sectors like mobile electronics and other spaces, where being lightweight is essential. Moreover, SMD components use fewer materials, creating a more straightforward and conscious production method.

Disadvantages

- Complicated Repairs and Redesign: Due to the parts’ reduced dimensions and the surface-mount design of SMD components, which makes accessibility and alteration a more significant challenge than through-hole parts, fixing or modifying them can be challenging.

- Resolving Difficulties: There is a greater chance of harm or misplacing throughout assembling and maintenance since minuscule SMD components tend to be increasingly fragile and difficult to work with.

- Need for Specialty Machinery: Surface mount components production necessitates using expensive initial expenditures on specialist equipment from the biggest machines to the most miniature tools.

- Durability Challenges: SMD component interactions can often fail to be as robust as conventional process-produced intersections, which may cause dependability problems in adverse environmental circumstances or physical stress.

- Increased Need for Accuracy: Certain applications might encounter difficulties when implementing SMD parts installation because of the increased accuracy required in creating and production procedures to guarantee precise element positioning and bonding.

The manufacturing and implementing surface mount device components need expert supervision to ensure product durability, stability, and reliability. These components are essential for a broad and diverse array of applications, including consumer electronics and applications that indirectly impact end-consumers, such as applications in medical equipment and the aerospace industry. Ensuring that these components are manufactured and placed currently is pivotal in ensuring the safe, efficient, and effective functioning of the gadgets or appliances wherein they are utilized.