Mobile PCBs – Importance & Essential Design Elements

The term’ mobile communications PCB’ describes the customized type of printed circuit boards found in handheld communication devices such as tablets and cell phones. Such PCBs are made to make integrating different electrical parts essential for data handling, wireless connectivity, and device performance easier in a small and effective package. Their complex circuits, which include memory, power control, interfaces, and signal conditioning, are tailored to fit into the constrained area of portable electronics. With features like cellular connection, Bluetooth, etc., which are necessary for contemporary handheld electronics, mobile communications PCBs facilitate the smooth functioning of wireless connections.

Meaning of Mobile Communications

Mobile communication is the transfer of records, media material, and data among portable electronics over wireless connections. It includes all of the innovations that enable communication with portable electronics like cell phones, tablets, and smartwatches. These include phone conversations, texting, email correspondence, online shopping, social networking engagement, and wirelessly shared multimedia. Mobile communications use a variety of innovations, including satellite communications, WiFi, Bluetooth, and mobile networks. These developments provide omnipresent connections, enabling people to interact, maintain links, and get data no matter where or how portable they are.

Mobile Communications PCBs’ Impact on Mobile Communications

Mobile PCB significantly impacts the functionality, operations, and overall seamless and efficient performance in mobile communications. These specialized printed circuit boards make a mark on the entire spectrum of mobile communications functions. Some of the critical impacts include the following:

- Small-scale Designing and Integration: Mobile communications printed circuit boards are designed to hold numerous parts in a restricted area. The flawless operation of handheld electronics is made possible by their small layout, which enables the incorporation of crucial components, including chips, memory, antennae, power control networks, and networking components.

- Signal Processing and Effectiveness: The signal analyzing within these electronic components is tailored to provide effective communication, information, and multimedia information transfers and receptions. The mobile PCB parts and lines are arranged deliberately to reduce disruption, boost signal quality, and increase overall interaction effectiveness.

- Improved Network Integration and Connection: The circuitry supporting several forms of wireless communication, including cellular connections, Bluetooth, WiFi, and NFC, is integrated into printed circuit boards in mobile communications gadgets. In order to provide dependable interaction and information exchange, their design and arrangement substantially influence gadget connection, network reliability, and signal integrity

- Assistance with Sophisticated Features: The potential and improvements within mobile communications PCB technologies are critical to the progression of mobile communications, particularly the deployment of sophisticated features such as media downloading, virtual realities, satellite navigation, lightning-fast data transmission, and even Artificial Intelligence apps.

Critical Features

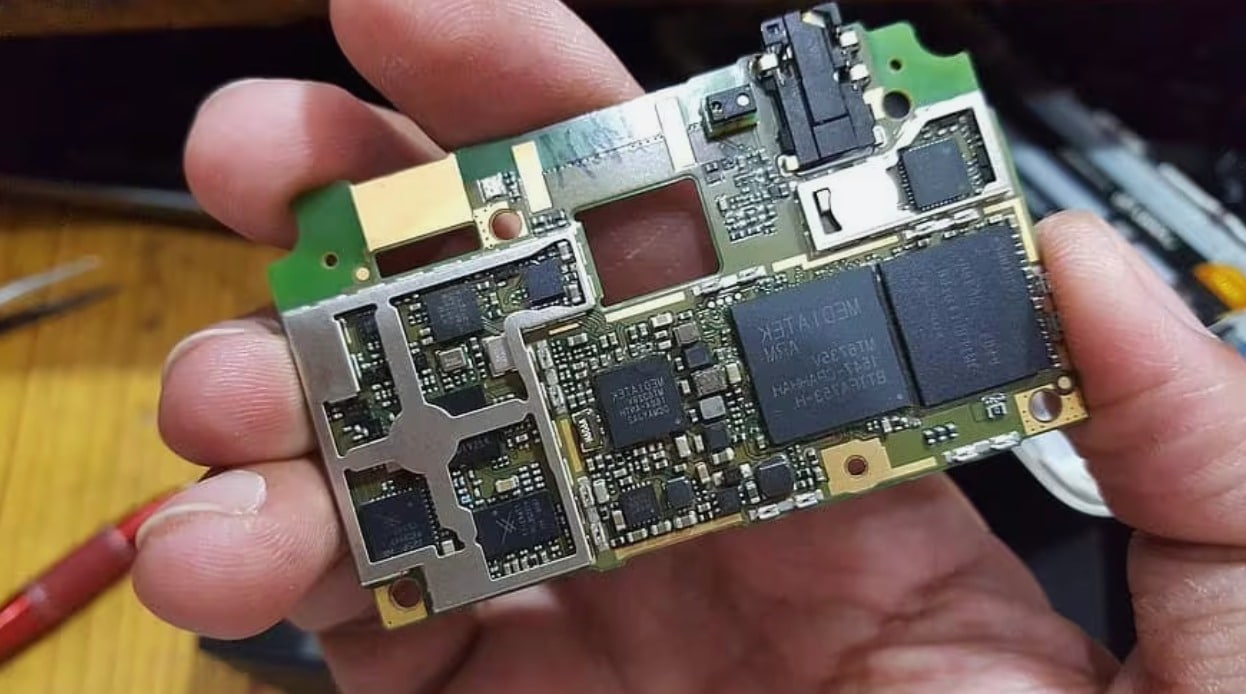

A mobile PCB board comprises various parts and features, each performing a different function for mobile communications. Each of these critical components is vital for the proper functioning of mobile communications. The main components include the following:

- Oscillators and Clock Generators: To ensure that the various parts of the gadget operate in unison, these elements produce the clock signals needed for sequencing and synchronizing.

- Substances that Anchor and Guard: Mobile communications PCB commonly include protection elements, such as grounding planes and barriers, to increase electromagnetic compatibility (EMC) and reduce EMI, or electromagnetic interference, while maintaining signal quality.

- Microcontrollers and Microprocessors: These operations include processing information, computing, and functionality management. They constitute the neural networks of the handheld device. Utilizing app processors to handle intricate computer systems apps is commonplace in sophisticated handheld gadgets.

- Inactive Elements: A fundamental, inert element utilized for voltage control, resistance pairing, and signal processing on a mobile phone PCB includes an inductor, resistor, and capacitor.

- Power Management Integration Circuits (PMICs): To ensure effective functioning and prolong the life of the batteries, these phone PCB parts control the energy supply, oversee the charging of the batteries, and control power use within the gadget.

- Sensors: Many kinds of sensors are included in handheld electronics, including gyroscopic elements, proximity detectors, and ambient light detectors. Such sensors offer greater user comfort and functionality by providing data about the gadget’s direction, movements, and closeness to items, as well as the amount of ambient light and magnetic fields.

- Links and Interfaces: SIM card spaces, SD card openings, headphone connectors, USB outlets, and monitor connections are just a few of the components and interfaces on a mobile PCB board. They make transmission of data, peripheral gadget interaction, and other connections easier.

Steps in Designing Mobile Communications PCB

Mobile phone PCB design is a comprehensive process that consists of various steps. The most critical processes involved in the successful completion of this task include the following:

- Element Arrangement and Location: Effective component positioning upon the printed circuit board design on the phone PCB is essential. The careful arrangement of components improves overall efficacy by minimizing signal route dimensions, increasing signal authenticity, and reducing signal disruption.

- High-Frequency Designs and Signals Dependability: Signals with elevated frequencies are used in mobile communications. Manufacturers are responsible for minimizing electromagnetic interference (EMI), signal degradation, and bounces to ensure signal quality. Regulated resistance architecture, resistance pairing, and correct tracing routes are crucial for fast signal propagation.

- Handling Heat: Many parts of handheld devices operate by producing heat. Effective heat dispersion via the printed circuit board layout—such as the placement of heat drains, thermal channels, or copper flows enabling thermal distribution—is essential to avoid overheating and preserve device efficiency.

- Adherence to Statutes: When developing Mobile Communications PCB for mobile communications, statutory criteria and licenses about security and electromagnetic compatibility must be followed.

- Assessment and Evaluation of Designs: The efficiency and dependability of a printed circuit board design are guaranteed by extensive design validation using models, prototypes, and tests. Before mass manufacturing, it is imperative to conduct tests for signal authenticity, thermal stability, and conformity with requirements.

- Versatility and Sustainability: The Mobile Communications PCB architecture can be designed to accommodate future improvements and adaptation, which makes it possible to integrate novel functions, elements, or innovations without having to rebuild the equipment thoroughly. This increases the gadget’s durability and agility.

- Decrease in Size and Sleek Structure: Mobile Communications PCBsmust strive for downsizing and smaller shapes because of the restricted space in handheld devices. Using multi-layer printed circuit boards, surface-mount devices (SMDs), and smaller boards is critical without sacrificing performance.

- Transmission and Control of Power: For portable electronics to maximize the lifespan of their batteries, effective power control is essential. Steady electrical supply is ensured to various parts of the gadget by appropriate ground plane design and power transmission, in addition to positioning power control devices such as filters or voltage controllers.

A mobile phone PCB is a critical element in ensuring seamless and appropriate functionality and efficiency of mobile communications. This specialized printed circuit board helps ensure the smooth operations of a wide range of mobile or portable devices. Designing these boards properly ensures that whatever gadget these are inserted into operates successfully. To do so, following the steps and procedures mentioned above in this article is essential.