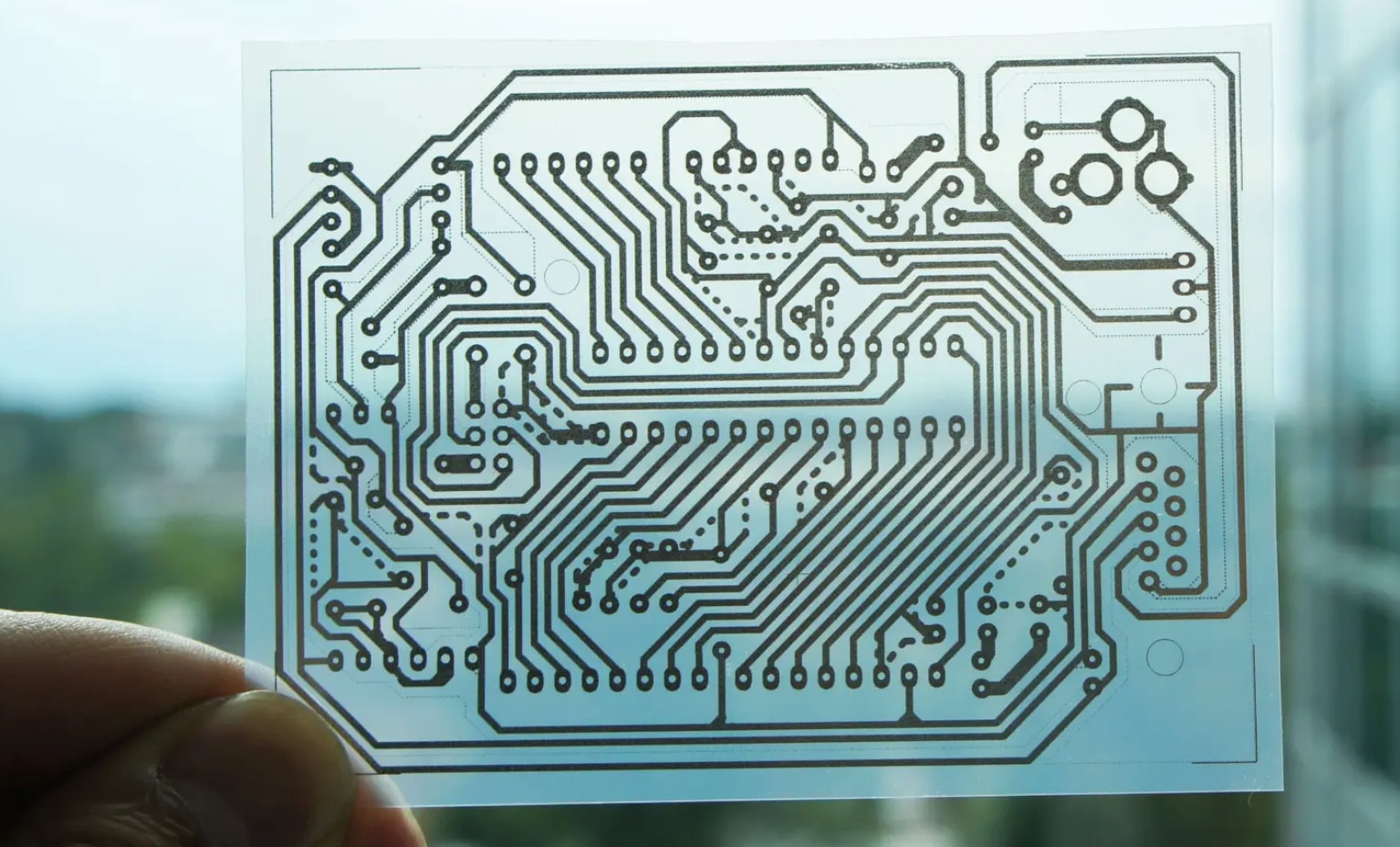

Circuit Printing Easy Way: Machine, Process and Cost

What is Circuit Printing?

Circuit printing is using printing processes to create electrical circuits on different surfaces. It is sometimes referred to as printed circuit technology. Electronic circuits could be formed without standard solder or etching because this creative method involves depositing conductive substances or inks upon the surface. In creating wearable gadgets and adaptable screens, as well as for additional purposes where conventional inflexible circuit boards would not be feasible, the circuit printing technique becomes especially helpful since it facilitates the production of lightweight and adaptable electronic gadgets

Technologies Used for Circuit Printing

- The Process of Inkjet Printing: An accurate and tightly controlled way of depositing inks that are conductive upon the material being printed is known as inkjet printing, a non-contact circuit printing process. This process is helpful for smaller-scale manufacturing and developing prototypes and may be applied to create complex designs.

- The Screen Printing Method: A template or screen deposits conductive printer ink on the backing material in the widely prevalent screen printing process. This circuit printing process may be used for larger-scale manufacturing and is adjustable, making it appropriate for solar power cells and flexible electronic devices, among other uses.

- The Microcontact Printing Method: Through this procedure of circuit printing, the conductive inks or materials are transferred on top of the base material layer through an elastomeric stamp with a pattern printed on it. Microelectronic device manufacturing processes often employ this technique, which works well for producing small-scale, high-resolution characteristics.

- The Aerosol Jet Printing Method: The Aerosol Jet Printing method is quite common for creating precise structures on a backing material. This circuit printing method employs a concentrated aerosol flow that consists of conductive nanomaterials. 3D electronics may be manufactured with this approach because it is flexible and capable of printing on various substrates, including irregular or multidimensional ones.

- The Electrohydrodynamic Printing Method: To manage the application of the conductive inks, the electrohydrodynamic printing method of circuit printing employs an electric field. Delicate details and complex arrangements may be created with this technique since it gives exact command over the ink particles during the manufacturing procedure.

- The Stencil Printing Method: Using a stencil tool for circuit printing, conductive material or inks can be easily applied to a surface precisely through stencil printing techniques. Conventionally, electronic parts on stiff circuit boards are produced using this process as it makes it more effective.

Advantages of Circuit Printing

Versatility of Design: Electrical circuits that are both elastic and adaptable may be created through circuit printing, allowing designers to create gadgets that can adapt to various substrates and forms. Products such as smartwatches or other pieces of wearable technology and versatile screens benefit greatly from this adaptability.

Fast Prototype Development: Rapid prototype creation is made possible using additive manufacturing methods in circuit printing. Fast implementation of layout modifications lowers the time and expense of the initial prototype phase for creating electrical devices.

Individualization and Customizing: Electronic gadgets may be made uniquely and customized with the help of circuit printing practices. Producers of a wide array of devices may quickly modify the circuit layouts to satisfy certain specifications, and customers may obtain customized electronic parts made to fit their demands.

Minimized Material Wastage: Repetitive techniques such as etching are frequently used for conventional circuit board production, which wastes materials. As an additive production method, circuit printing reduces wastage and deposits components exactly where they must be, promoting more environmentally friendly production practices.

Minimal Weight and Slender Shape: Lighter electrical components with a tiny form factor are produced by circuit printing on slender, adaptable substrates. Systems wherein weight and dimensions are crucial, such as handheld devices and aircraft, would benefit most.

Scalability for Large-Scale Manufacturing: For large-scale manufacturing, several circuit printing techniques are adaptable, including screen printing and flexographic printing techniques. Because it can be scaled up or down to meet larger production needs, circuit printing improves the effectiveness and profitability of manufacturing operations.

Multi-Substrate Interoperability: Among the many surfaces that may be used for circuit printing are plastics, paper, and fabrics. Due to its broad surface connectivity, electronic functioning can be integrated into a more comprehensive range of unusual substances and purposes.

Superior Clarity and Accuracy: Superior resolution and accuracy are features of several circuit printing techniques, such as microcontact printing and inkjet printing. This capacity makes it possible to incorporate beautiful aspects into electrical devices and to create complex circuit layouts.

Cutting-edge 3D Printing Opportunities: Electronic parts may be created on three-dimensional materials using aerosol jet printing and other 3D printing techniques in circuit printing. This breakthrough increases the opportunities for integrating electronics into intricate constructions and gadgets.

Economical Experimentation and Low-Volume Manufacturing: Low-volume manufacturing and affordable design of prototypes are made possible via circuit printing. Manufacturers can get new electrical items into the marketplace more rapidly and with lower installation expenses because of rapid prototype iterations.

Possibility of Internet of Things Utilization: Circuit printing is a flexible and adaptable method ideally suited for fabricating electrical parts for Internet of Things applications. Circuit printing gives these electronics an edge over others as they often necessitate customized layouts and integration into various contexts

With so many advantages to its credit, circuit printing is an advantageous method utilized widely in manufacturing practices for various electronics, particularly portable and wearable electronics. Manufacturers can create highly versatile and scalable layouts by following appropriate manufacturing practices and industrial standards, in addition to best designing practices for creating intricate circuit patterns. These scalable options can benefit both small-scale and large-scale manufacturing businesses.