What is the Standard PCB Thickness

Printed Circuit Board (PCB) acts as the base for most of the electronics. PCBs are simple in structure and generally consist of only one layer. The most common association of PCBs is with computer hardware; however, it is also used in radios, televisions, cell phones, etc. The Performance of a PCB is determined by various factors, such as manufacturing material, cost, fabrication, prototype, etc.

[wpi_designer_button twin_id=2164]

Additionally, PCB thickness is also a very crucial influence on overall performance and durability. It affects the PCB’s resistance and conductivity; hence working on the perfect thickness is a must. Whenever we talk about a ‘standard’ feature or a benchmark measure of certain items, we refer to the perfect feature we hope to attain. So that our product stands and clears all tests of performance, weight, durability, reliability, and above all, quality. The introduction of Aluminum to manufacture PCBs is another step to make it more accessible, affordable, and efficient. Initially, it was just copper foils that were used to build it.

PCB Sheets: there are no set standard thickness measures for a PCB sheet; however, the market value and preference determine the standard PCB thickness or the most commonly used one. To attain an extensive thickness, one can combine a range of prepreg sheets and various core thicknesses. There are various PCB Thickness Options available in the market.

What is Standard PCB Thickness?

The current standard PCB thickness lies in these ranges: 0.031in (0.78mm), 0.062in (1.57mm) and 0.093in (2.36mm). However, the most commonly used thickness is 157mm or 0.063inches. But it should also be kept in mind that users or applications also determine the circuit board thickness standards. Initially, plywood was used as a substrate, and the resulting thickness was more. With advancement, better options have come up, for example, epoxy.

PCB Copper Thickness

The most dominant and prevalent metal in functionality and application of PCB is Copper. It is so because it is comparably smoother to achieve a standard board thickness with Copper, which measures approximately an ounce (oz). Also, a very thin PCB thickness can limit the surface finish options available.

There are various manufacturing and design specifications and factors that need attention; some of them are:

The Design factors that impact and affect PCB thickness

1) Significant Cost Factors: determined by:

- PCB size

- Number of Layers

- Yield

2) PCB Complexity:

- Number of layers

- Number of vias

3) Materials used: the selection for the material is based upon:

- Operational speed

- Frequency

- Operating temperature (Max.)

4) Operating Environment

The Manufacturing Factors that impact PCB thickness

- Size and number of holes

- Copper Thickness

- Tolerance

- Surface Finish

- Depanelization method

- Gap and track geometry

How to Specify PCB Thickness?

Trace width calculators are used to specify the PCB thickness. It functions similarly to a normal calculator; you need to input all the details and specifications, and the calculator provides you the required thickness. To make an accurate and efficient judgment, the calculator facilities and offers a calculation up to the hundredth of a millimeter. The thicker aboard, the less are the chances of wear and tear; however, if the application calls for the thickness should be kept under a measure.

[wpi_designer_button twin_id=2164]

Factors to keep in mind while choosing the thickness of PCBs

Following are the factors and specifications that need to be kept in mind while deciding the thickness of a PCB board for better endurance and performance:

- Weight

- Flexibility

- Impedance matching

- Required space

- Connection

- Component compatibility

- Design requirements

What If I Want a Custom Thickness?

Sheets or panels used for manufacturing PCBs are easily available in the market. There are various customization options that offer designs and thicknesses as per your specifications and needs. You can pick the thickness range from 0.2mm to 6.3mm in millimeter increments of a hundredth. Read further to find out factors that must be supervised while opting for a customised PCB board thickness.

Factors to keep in mind for Custom PCB Thickness

1) Turnaround time: Generally, the expected turnaround time to receive a customized PCB layer thickness is more due to the uncommon thickness specifications. This will impact your delivery schedule and development timing.

2) CM’s equipment capabilities: If you do not want to compromise in your design and model, be careful while choosing your CM. If your CM has limited options of equipment to manufacture and design the typical PCB thickness you are looking for, you will have to compromise and modify your PCB layout.

3) Additional costs: Customization costs are generally higher due to the additional details and expectations. The use of specific material, design, and adhering to a detailed set of instructions amounts to additional manufacturing costs than usual prices.

Using customized thickness can increase the design appeal and yield, providing it an exclusive performance and value. However, using multiple layers can be very costly due to extra processing, manufacturing steps, and materials.

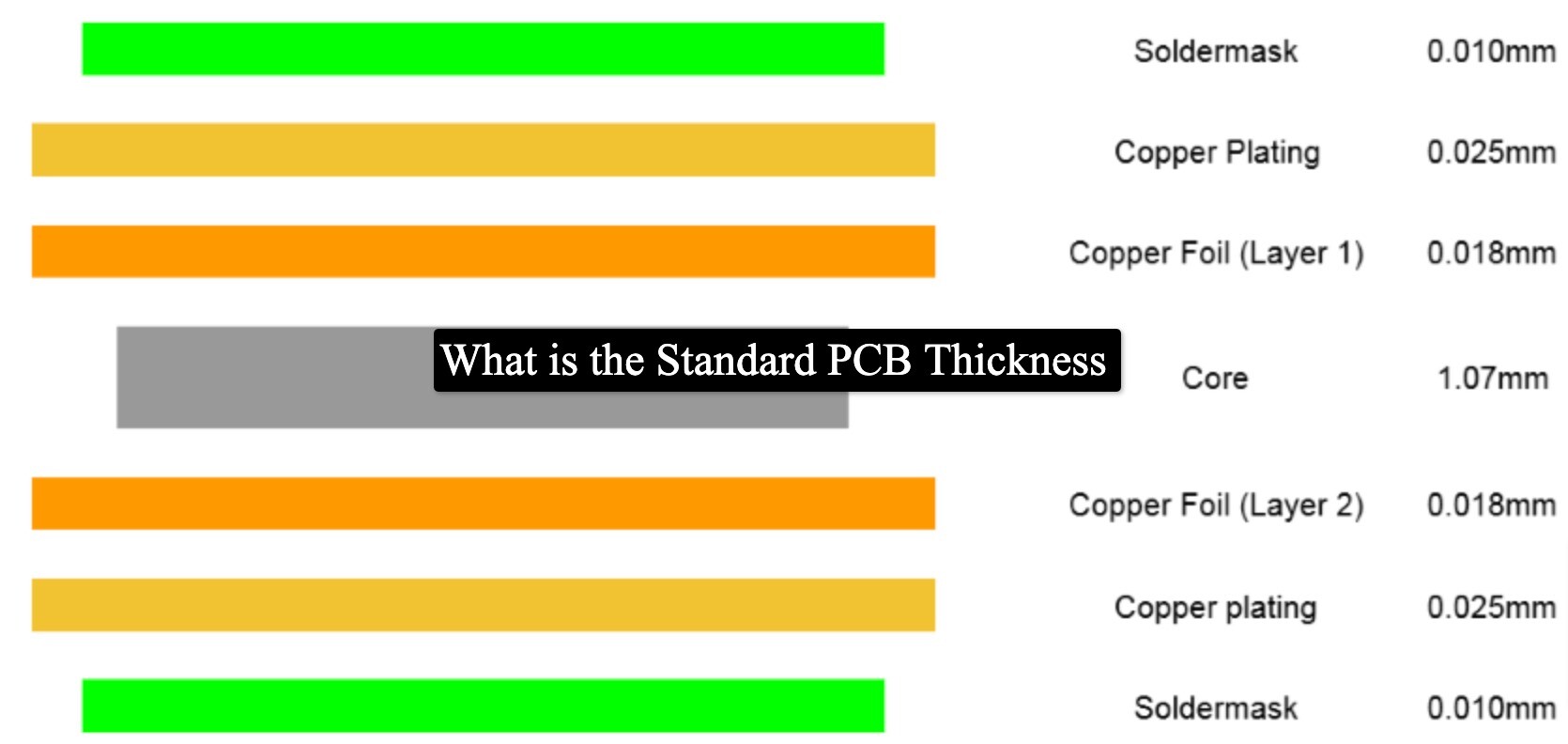

With a perfect manufacturing partner, the desired thickness can be achieved smoothly. The first step to customization is generally determining common core prepreg thickness and combining it in a perfect sequence with copper plating, copper foil, and solder mask.

We, at Absolute Electronics, take care of your needs with high-quality, accurate prototypes. We can cater to all your standard and customization needs with good designs and intent. Few highlights of our Custom PCB Manufacturing Service:

- Accurate quote within 24 hours

- The entire turnkey process performed within or less than three days

- Reduced procurement time

- Dedicated and committed Quality Certification

- High PCB quality

- Automated Optical Inspection

Try our service by sending a quotation request to sales@absolutepcbassembly.com. Get your designs manufactured with the quality delivered to you in no time. We take quality with utmost sincerity.

Click here to send your files fast and securely to us!

[wpi_designer_button twin_id=2164]