What Cost to Make Custom PCB Printing ?

What is Custom PCB Printing?

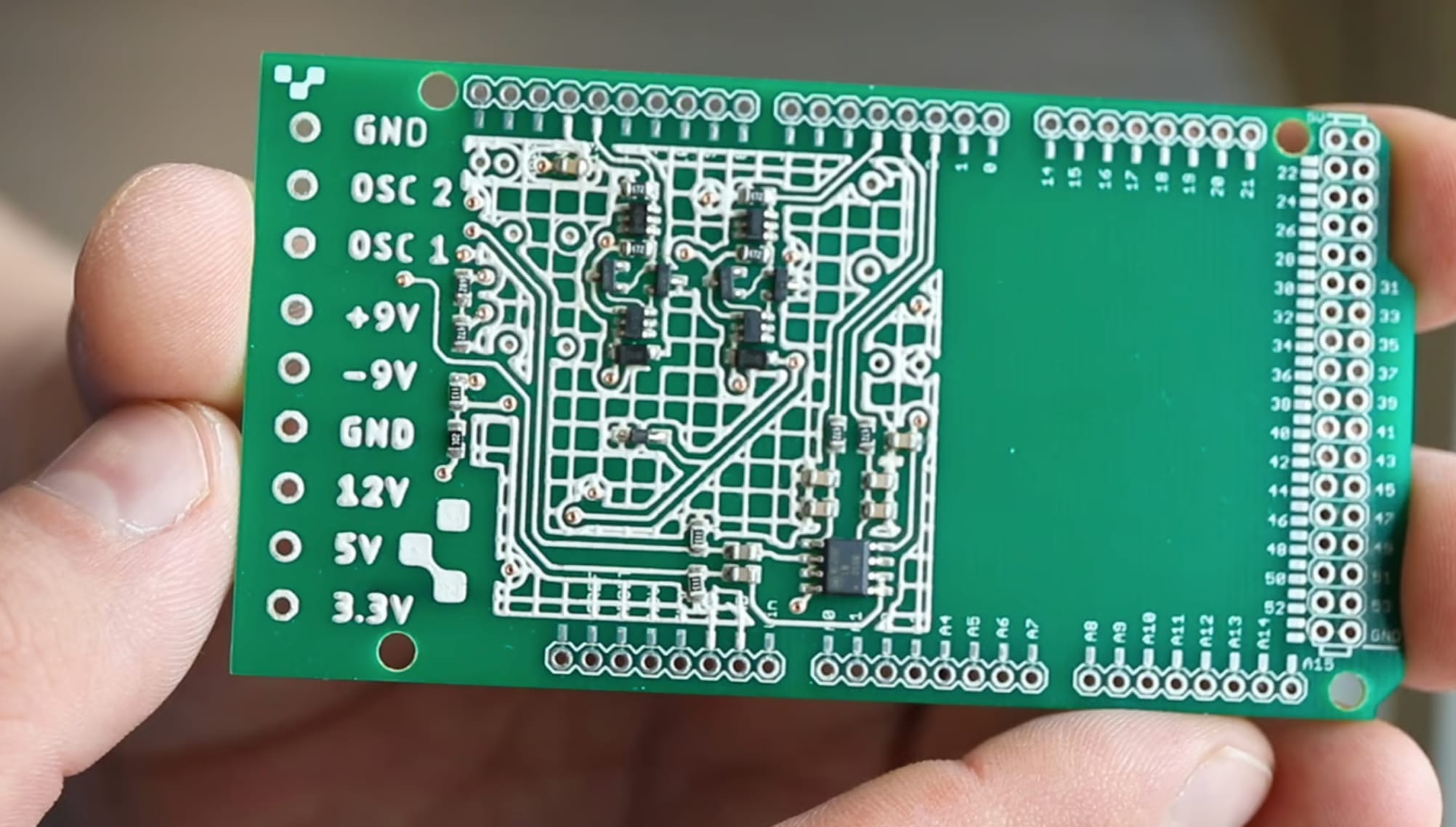

Designing and producing printed circuit boards, particularly for a particular set of specifications, use cases, or one-of-a-kind electronic gadgets, is known as custom PCB printing. Making a PCB layout specially adapted to an electrical circuit’s dimensions, functioning, and connectivity requirements is known as customization. Custom PCB printing enables the incorporation of different elements, such as resistors, capacitors, and integrated circuitry, according to the exact needs of the electrical infrastructure. Through customization, both functionality and performance are optimized for a wide range of gadgets and businesses. Many associated costs need to be assessed before beginning customization.

Factors Determining Custom PCB Printing Costs

Level of Design Intricacy: Pricing is mainly determined by how intricate the PCB design is. The increased cost of custom PCB production results from the need for more accurate production processes for complex patterns with many layers, thin traces, and minor elements.

Number of Layers: Difficulty during production is influenced by a PCB’s layer count, thereby impacting custom PCB printing costs. When comparing multiple-layered PCBs with single or double-layer panels, the former often have higher prices due to multiple electrically conductive materials divided by insulation material layers.

Element Density: Production difficulties are affected by the PCB’s element density. Complex assembling methods may be needed for high-density layouts with many parts and compact tracks, raising PCB printing costs.

Board Dimensions: A major consideration that impacts the cost of custom PCB production is the actual dimensions. Additional materials and production time requirements for larger boards might affect total expenditures. However, more precise manufacturing processes may be required for smaller panels, which can also increase costs.

Materials Utilized: Custom PCB printing costs are also impacted by the printed circuit board material choice, including the kind of substrate and copper layer thickness. Price increases may result from using expensive components, particularly those made for specialized services like high-frequency circuits.

Production Quantity: Prices for custom PCB printing are influenced by the number of printed circuit boards bought per unit. Savings associated with bulk manufacture usually result in lower costs per PCB. Higher expenses per piece might be related to experimentation or small-scale manufacturing.

Manufacturing Turnaround: Increased custom PCB printing expenses are frequently associated with accelerated manufacturing timelines. Producers might ask for more if you want a shorter processing timeline.

Surface Finishing and Coating: Custom PCB printing costs can be affected by the surface finishing used on the printed circuit boards, such as soldering masks or gold plating. Although they cost more, some finishes might improve effectiveness and sturdiness.

Unique Prerequisites: PCB printing costs may rise due to unusual requirements like resistance management, hidden channels, or components designed for specific settings. Extra production stages are frequently required to meet tailored needs, increasing costs.

Range of Custom PCB Printing Expenses

Prototype Creation and Small Batch Productions: Costs for custom PCB printing might vary from $100 to several thousands of dollars for small-scale endeavors or prototype developments. In comparison to more extensive runs of manufacturing, experimental printed circuit boards sometimes have higher prices per unit because of setting expenditures.

Medium Batch Production Sizes: An average medium manufacturing run for custom PCB printing can cost anywhere between fifty cents to twenty dollars for every square inch, with runs generally numbering in the few hundred to several thousand pieces. As manufacturing quantities increase, economies generated by scale cause prices to go down.

Large-scale Manufacturing Runs: The custom PCB printing costs per square inch of surface can be reduced to as low as $0.10 to $5 in large-scale manufacturing runs comprising hundreds of thousands of pieces, according to the degree of complexity and components utilized.

Premium and Specialized PCBs: More expensive custom PCBs are the outcome if they require superior materials, innovative characteristics, or unique specifications. These undertakings may cost several thousand dollars according to the particulars of the circuit boards.

Advantages of Custom PCB Printing

Application-Dependent Capabilities: To improve the customized PCB’s usefulness for particular uses, developers might include elements exclusive to the usage, including sensors, connectors, or additional features.

Optimizing Space: Designers may maximize the arrangement for small electrical components by utilizing custom PCB printing, which effectively uses available space. This is especially helpful for businesses wherein size restrictions are essential.

Enhancing Efficiency: Customizing the printed circuit board layout enables the electrical system to suit its unique requirements by improving its performance characteristics, including power distribution, capacitance management, and signal quality.

Low-Cost Prototype Development: CustomPCB printing promotes affordable prototype development by enabling quick design iterations. Accelerated stages of action may be the outcome of this adaptability during the prototype stage.

Adaptability of Materials: Developers can select specific materials according to the needs of the usage of their custom PCBs, guaranteeing that they are compatible with the surrounding environment, temperature concerns, and other elements.

Incorporation of Innovative Functionalities: Complex electronic devices may be developed by incorporating sophisticated characteristics like high-frequency circuits, high-quality finishes, and resistance-matched tracks made possible by custom PCB printing.

Increased Dependability: Choosing premium components for custom PCB printing and adhering to strict guidelines are made possible by creating a customized printed circuit board, which increases the electronic device’s lifetime and dependability.

Distinctiveness and Innovation: Custom PCB printing allows electrical device developers to be creative and unique. Items can stand out in the competitive marketplace and satisfy specific consumer demands due to their unique design elements.

Tailored Form Elements: Manufacturers may fit the PCB form to the goods or application’s shapes by using custom PCB printing practices, which make it possible to create electronic gadgets with distinctive shape characteristics.

Custom-printed circuit boards are highly effective for applications requiring specific features to function seamlessly. By opting for these types of PCs over generic options featuring the same designs and functionality capabilities, product manufacturers can easily stand out in the market and offer a unique experience to customers.