Ceramic PCB Manufacturer

With the growth of technology, we are witnessing a change in the traditional circuit boards used in electronic gadgets. Presently the ceramic PCB or the ceramic printed circuit boards that use the ceramic PCB substrate are widely used in the electronics industry. This type of circuit board is a viable option better than the traditional printed circuit board as it is more versatile and offers better performance. The ceramic PCB also has high thermal conductivity and minimal expansion coefficient. From the perspective of the ceramic PCB manufacturer, here are some features of the new and improved ceramic PCB:

What is a ceramic PCB?

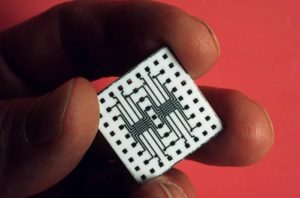

Ceramic Printed Boards or ceramic PCBs is highly conductive material like alumina, aluminum nitride, and beryllium oxide. The thermal conductivity of ceramic PCB makes it capable of transferring electrical signals like any other circuit board. The ceramic PCB substrate can efficiently dissipate heat from one circuit section to another. The image below will give you an idea of a ceramic PCB.

Fig 1 Ceramic PCB

The thermal conductivity of the ceramic PCB ranges from 9-20W/m. This means the ceramic PCB substrate can quickly transfer the heat from the spot where it is being generated to the entire surface. This makes the circuits useful in types of machinery like capacitors and transformers. In addition, think of machinery requiring high-frequency data transfer or high-frequency electrical transfers. Here it becomes necessary to have circuits capable of quick dissipation of heat. The ceramic PCB is precisely suited for this function, making it one of the highly used circuits in modern electronics.

What are the advantages of ceramic PCB?

When you use the ceramic PCB, the first advantage that you will come across is the durability of the circuits. These do not get damaged easily. There are several other advantages of the ceramic PCB, some of which are as follows:

High thermal coefficient of ceramic PCB

The high thermal coefficient expansion of the ceramic PCB makes it suitable for various electronics. For example, you can use it in isolators and electronic devices where there is a requirement for thermal conductors. In addition, the high thermal coefficient is necessary to help in stabilizing the devices.

Ceramic PCB provides better stability to devices.

The ceramic PCB substrate offers better stability and ensures your device lasts longer when it comes to solvents and moisture. The stability offered by the PCB is due to the dissipation of heat. This is an essential quality of PCB circuits that will make the devices last longer.

Ceramic PCB boards are both adaptable and durable.

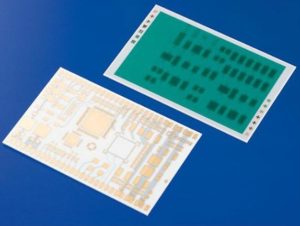

The ceramic PCB boards are durable because they are manufactured through fabrication. As the PCB boards have a slow aging process, you will find that the circuits do not need changing. Moreover, the metal core in the circuits of the ceramic PCB makes it easier to be used in both fluids and solids. This is where the adaptability of ceramic PCBs comes into play. It makes it easier to be used across various industries in the electronic market. The image below will help you understand the multiple uses of ceramic PCB.

Fig 2: Multiple uses of PCB

Main Ceramic PCB Types or the different types of Ceramic PCBs

There are three different types of ceramic PCBs, and they are as follows:

- High-temperature ceramic PCBs

- Low-temperature ceramic PCBs

- Thick film ceramic PCBs

The features of these types of ceramic PCBs are as follows

High-temperature ceramic PCBs

These are the most commonly used PCBs, and they can withstand high temperatures. The circuit is made using raw ceramics with solvent, mixing adhesive, plasticizer, lubricant, and aluminum oxide. The ceramic PCB substrate can withstand temperatures as high as 1600 to 1700 degrees Celsius for nearly forty-eight hours. This makes the boards highly useful in the aerospace industry. The circuit is achieved using tungsten and molybdenum. The HTCC circuit is completed in a gaseous environment, like hydrogen gas.

Low-temperature PCBs

The substrate for this PCB is made by combining gold paste with crystal glass and then baked in an oven. This PCB can withstand temperatures up to 900 degrees Celsius. The PCBs have excellent conductivity and make them ideal to be used in LEDs and other heat dissipation products.

Thick film ceramic PCBs

As the name suggests, these circuits are used where you require a conductor exceeding the thickness of ten to thirteen microns. The conductor layer has silver palladium on the surface with dielectric circuitry. The primary advantage of the thick film PCB over the regular film one is that it can prevent the copper from oxidizing. This is why using these in semiconductors, electric capacitors, and resistors. These circuits need to be laser trimmed to achieve the desired thickness.

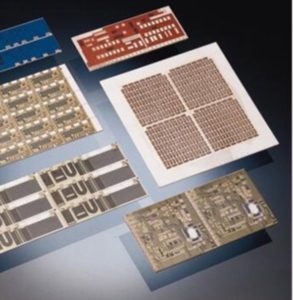

The image below will give you an idea of the different types of PCBs.

Fig 3: Different types of PCBs.

What is Ceramic PCB Thermal Conductivity?

As PCBs are used in hi-tech environments, you need to check the thermal conductivity of the circuits. Thus, thermal analysis of the PCB is essential to evaluate the heat transfer processes of the multiple components of the device. The PCBs are often used in environments with multiple temperatures, and it is essential to evaluate how well the individual circuits conduct the heat in the environment. The heat transfer capability of PCB is evaluated against several parameters such as radiator shape, heat dissipation rate, transmission efficiency, and operation condition of the entire device. Based on all of these conditions, the conductivity of the PCB is measured.

How to estimate Ceramic PCB Thermal Conductivity?

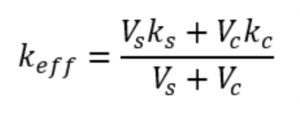

The thermal conductivity is calculated by evaluating the heat flux between the hot and cold regions of the circuit. One way of calculating it would be to check the material datasheets and then check the substrate’s thermal conductivity; when you make the calculation keep in mind the copper used in the circuits. The overall formula used in calculating the thermal conductivity is as follows:

In the given formula,’ is the effective thermal conductivity of the substrate, and ‘c’ is that of copper. The conductivity here will give you an idea of the thermal resistance and the heat back up in your stack. Once you have evaluated the heat backup, you can estimate the formula’s thermal conductivity.

What are the Ceramic PCB Applications?

We can assure you that ceramic PCBs have several applications as ceramic PCB manufacturers. In the field of communication, you will find that PCBs are used in smartphones, smartwatches, tablets, and radios. You will also find that PCBs are used in your regular desktops, laptops, and even in servers used in satellite navigation. As one of the foremost ceramic PCB manufacturer, we can assure you that the uses of these circuits are varied.

Contact Absolute PCB For Your Ceramic PCB Today

If you want to know the ceramic PCB price suitable for your device, you need to contact us today. The ceramic PCB price will depend on the circuit you choose and the use of the particular circuit. At Absolute PCB, we will ensure that the ceramic PCB price is as per your budget and competitively provided. So give us a call to know more about the price and the circuit ideal for your device.