Cold Solder Joint – Definitive Guide to Soldering

Cold soldering is a common issue amongst electronics. Although it is not so common amongst the most well-known brands, it is quite prevalent in lousy and unwarranted electronics brands.

[wpi_designer_button twin_id=2164]

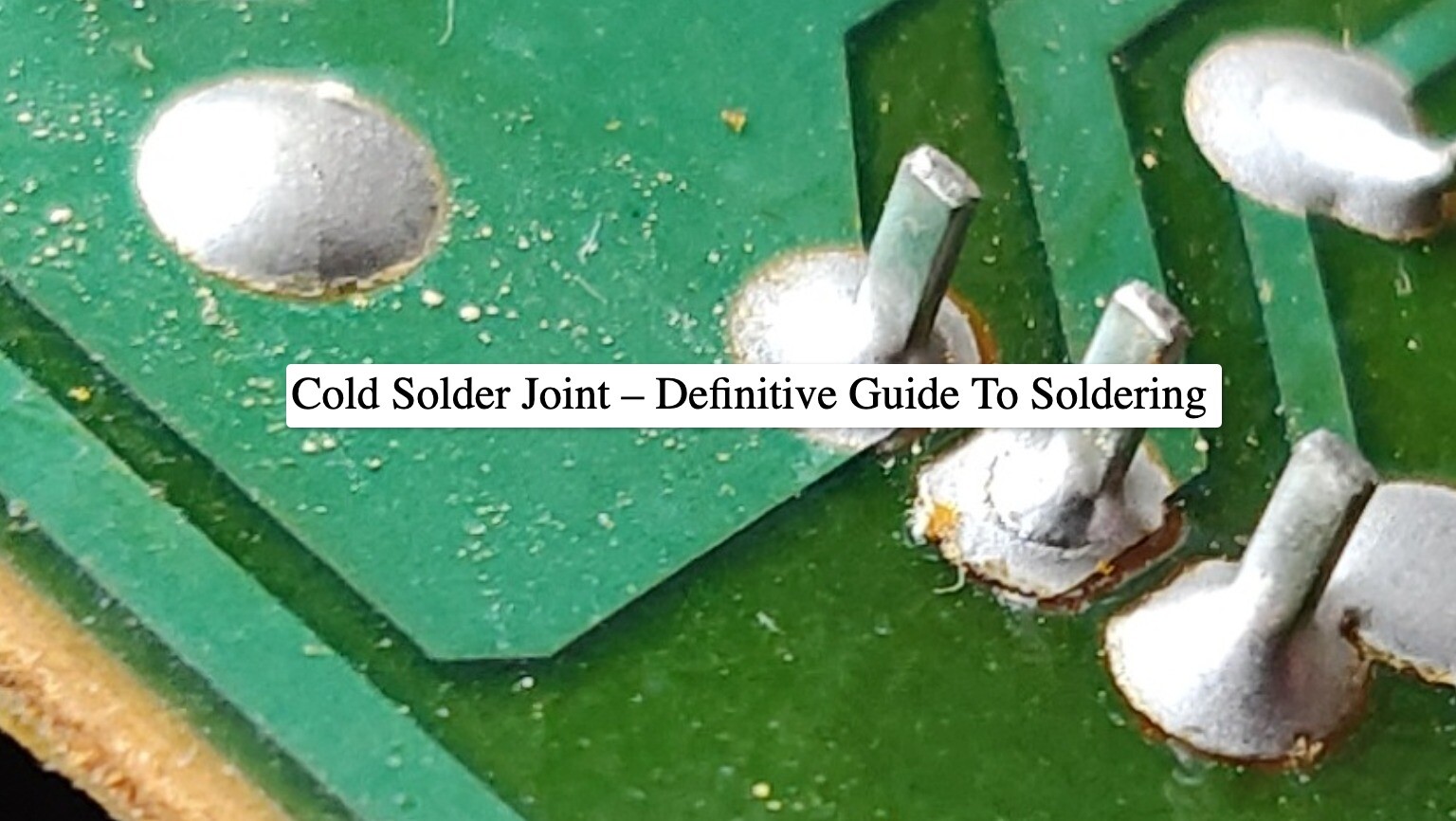

Cold Solder Joint

Before we proceed with explaining what a cold solder joint is, we shall take a look at what soldering is. In the soldering process, the electronics on a circuit board are connected with the help of a conducting alloy, which is molten and pasted in-between two connectors.

The process is accomplished with the help of a lead and tin alloy, which is available in the raw form of either a wire or rod. The alloy is heated with the help of a soldering iron, which is a pen-like instrument that can also be used for delivering the molten alloy. The soldering iron has a nib-like precision that allows the electricians to connect the smallest electrical connectors.

Cold soldering refers to using incompletely molten solders for making joints. These are usually lumpy and have coarse surfaces. Such cold solders do not work well for a long time. The lumps develop cracks over some time that can ironically detach the electrical connectivity despite its voluminous size.

Cold soldering is a usual issue amongst less-known or unbranded electronics. It is also seen increasing in relative new technological iterations like in the flexible PCBs. Using sub-standard soldering materials like the soldering iron or wire are other common reasons for cold soldering joints.

Cold Solder Joint Detection And Testing

Most electronics and electrical projects are assigned to freelance electricians. Such electricians also undertake bulk work.

Besides, the quality metrics with some less-known brands are also not that strict; hence, cold soldering is a common issue amongst such electronics.

Naturally, meeting the strict deadline with no worries of repercussions from the client leaves no option for electronic engineers but to complete their work without much neatness.

Many a time, such attempts to catch up with the backlog of work can lead to many problems. Many PCBs aren’t well-soldered and lead to componential failure. In the worst-case scenario, it can even lead to PCB failure.

This is when only one option is left with can lead to inadequate bonding and can, too, pave the way for a rework. Hence, cold soldering is a resorted practice as it gives convenience.

Such a practice can, needless to say, lead to loss of business; the clients will not outsource their component fixing needs. Besides, it can also cause loss of pay; the number of defective items will also lead to deductions in the payouts.

Therefore, it is quite necessary to ensure that you carry out the deft testing process even though you make cold solder joints.

[wpi_designer_button twin_id=2164]

Below are some standard tests for checking the cold solder joints’ conductivity

1- Visual tests for checking the cold solder joints’ functioning

This is the easiest and the most practical way of testing the cold solder joint’s workability. A simple visual inspection can help someone know whether the solder joint is a cold joint or not. A lumpy, uneven, or simply non-geometrical or extraneously applied soldering is regarded as a cold soldering joint.

Visually inspecting the cold-soldered joints may sound very simple; however, one may have to use visual aids like a magnifying glass and torch for checking whether the joints connect both the edges well or not.

If you can see the light passing through the joints, then it indicates an inadequately bond solder joint. Another thing to look for is rough blocks of solder joints; such joints indicate the soldering alloy’s inadequate heating. It can easily lead to cracking and detaching after the PCB gets hot during its use in the electronic item.

Moreover, loosely fit joints will at least partially detach from the base when you tilt the circuit board. Yet another thing, which is quite rare in occurrence, is to check whether the joint spills over to another one close by itself. It will inevitably create short-circuits and lead to the failure of the PCB.

2- Testing the cold solder joints with a multimeter

This method can be used in testing the cold joint’s workability in two ways as follows.

- 2a- Testing with a multimeter with the resistance

In this method, you can use the multimeter by switching it to 1000 ohms of resistance. You can begin by testing the multimeter by interconnecting the two terminals. You have to look for the reading ‘0 ohms’ to confirm it’s working.

Later, connect one terminal to one joint and the other terminal to the other joint. Here, too, the reading should be ‘zero’; anything more than that means a failed cold joint.

- 2b- Testing the continuity with a multimeter

In this test, you have to switch the multimeter to the continuity mode. Once again, test the device by connecting the two terminals; a successful continuity test will give a beep sound. Now, connect the two multimeter terminals to the two ends of the cold solder joint; a beep will indicate its working, and no sound means a rework.

With these two main testing methods, you can be sure that the solder joints will work despite cold soldering.

Cold solder joint repair

Once you have established that so many cold joints have problems conducting electricity, then there are two ways of fixing the problems. Below are the common types of cold solder joint problems and their solutions.

- Distributed cold solder joints

This is a common type of cold solder joint that occurs if the PCB or the soldering iron moves while pasting the molten soldering alloy.

A distributed cold solder joint looks concave and has a tilted pin. It also looks frosted and crystalline. Some people distinguish the distributed solder joints from cold solders as the metal is well-heated before soldering.

- Solving the distributed cold solder joints

To avoid the problem in the first place, you need to have a non-wiggling table fixed stably on the ground. You can alternatively use a wall-mounted soldering vice; it will work for space’s limitedness and offer a very secure structure.

2- Normal cold solder joints

As stated above, finding a cold solder joint is very simple. Apart from the haste of appropriate heating, it can also be caused due to the unclean soldering iron tip. A yet another common reason is the inadequate heating of the soldering iron.

- Solving the cold solder joints issue

The only way to solve the problem is by cleaning the soldering iron’s tip before using it. Also, keep the device in an airtight box that does not allow dust particles.

Besides, you have to see that the soldering iron does get heated well to be able to heat the soldering alloy.

Choosing SN96 solder, which is a lead-free solder alloy, can be viable as it has a lower melting point and plastic transition time.

- Key Cold Solder Joint Issues

As stated above, testing the cold solder joints’ resistance is the right way of checking their conductivity. It is worth mentioning the reason for the resistance on cold solder joints.

If the resistance is too high, then it possibly means the incomplete combustion of the alloy. It can lead to the ruining of the electronic immediately or take a toll on its life in the long run.

Incomplete circuits and overheated circuits and resulting increased power consumption are the common problems with increased resistance with the cold solder joints.

Key Soldering Practices You Need To Practice

As we have discussed already, cold soldering is not something we desire; after all, it is costlier than hot soldering as it makes us use more than the required alloy. Here are some acceptable practices we can take into account.

- Invest in the right products:- Choosing the right set of soldering items, namely the iron and alloy, are the best things to do to ensure that you have even and conductive solder joints.

- Use as low yet adequate solder amount as possible

- Keep the soldering iron and wire or rod in a dust-free and moisture-free environment, preferably in an airtight box

- Let the soldering iron heat sufficiently: – Doing this will make the solder joints less chunky and bumpy and also less in use

- If you commonly have issues with cold soldering, then use lead-free soldering wire or rod

- Go for a soldering gun that heats the wire or rod rapidly

- Work on a stable work desk while soldering

[wpi_designer_button twin_id=2164]

Conclusion:

Soldering is a way of making electrical connections. However, soldering in haste, not using the right materials, placing the tools in a dirty environment, or soldering on an unstable work desk can lead to cold soldering.

This can further lead to the deterioration of the joints, resulting in its malfunction, overheating, or overconsumption of power. With the tips mentioned above in the article, you can make sure that each of the solder joints functions optimally.

Also read:-