What we are known for

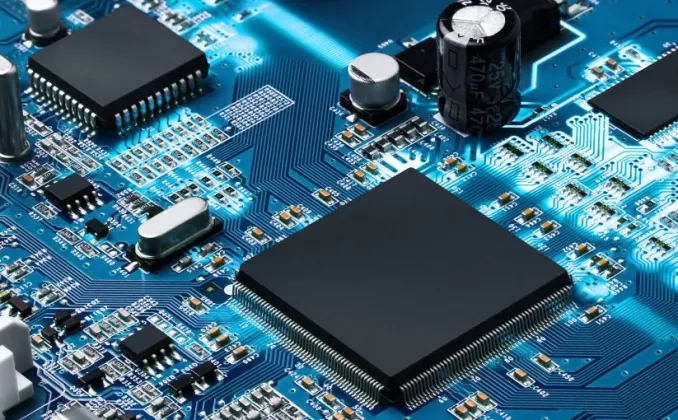

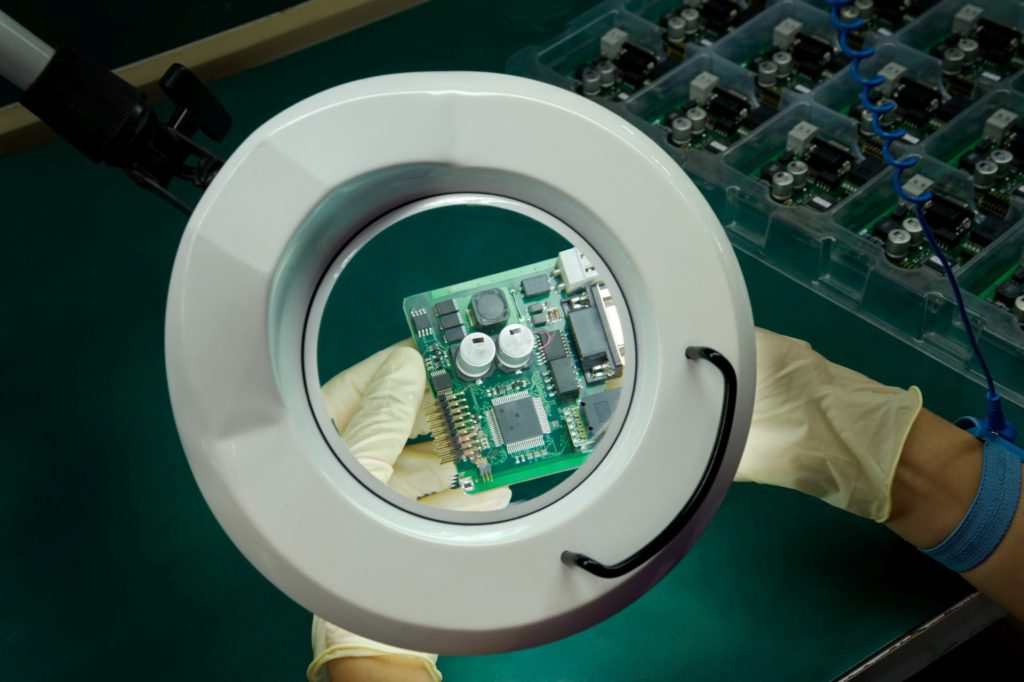

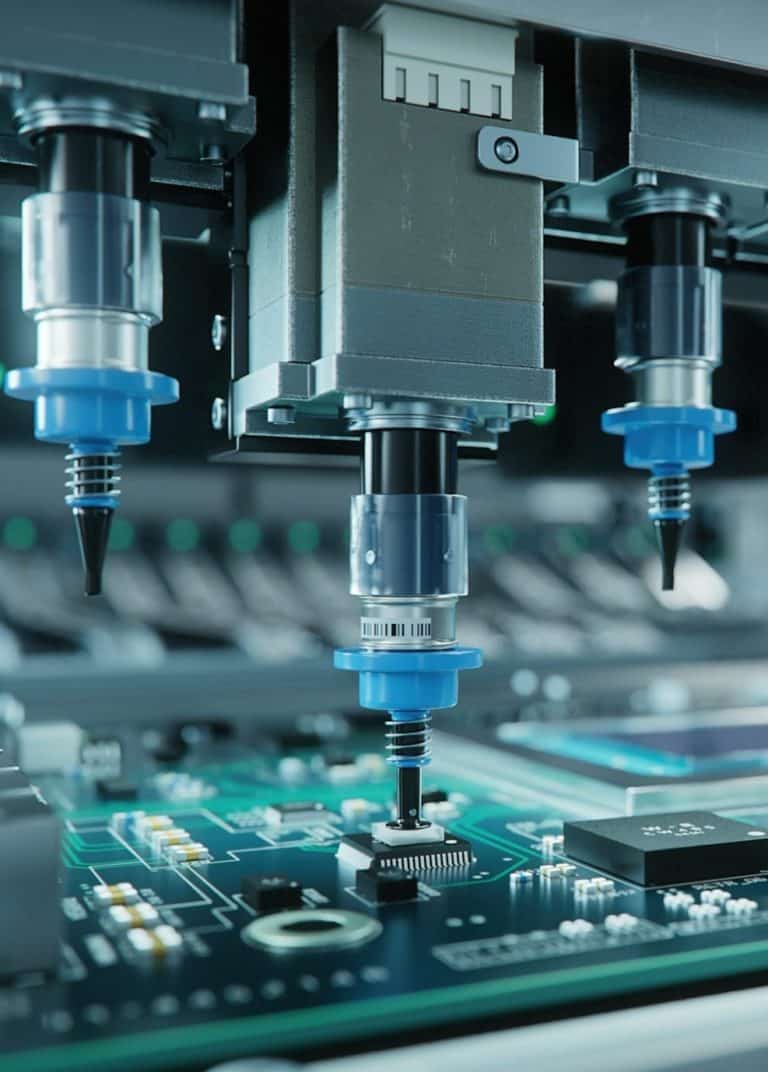

PCB Assembly Services USA

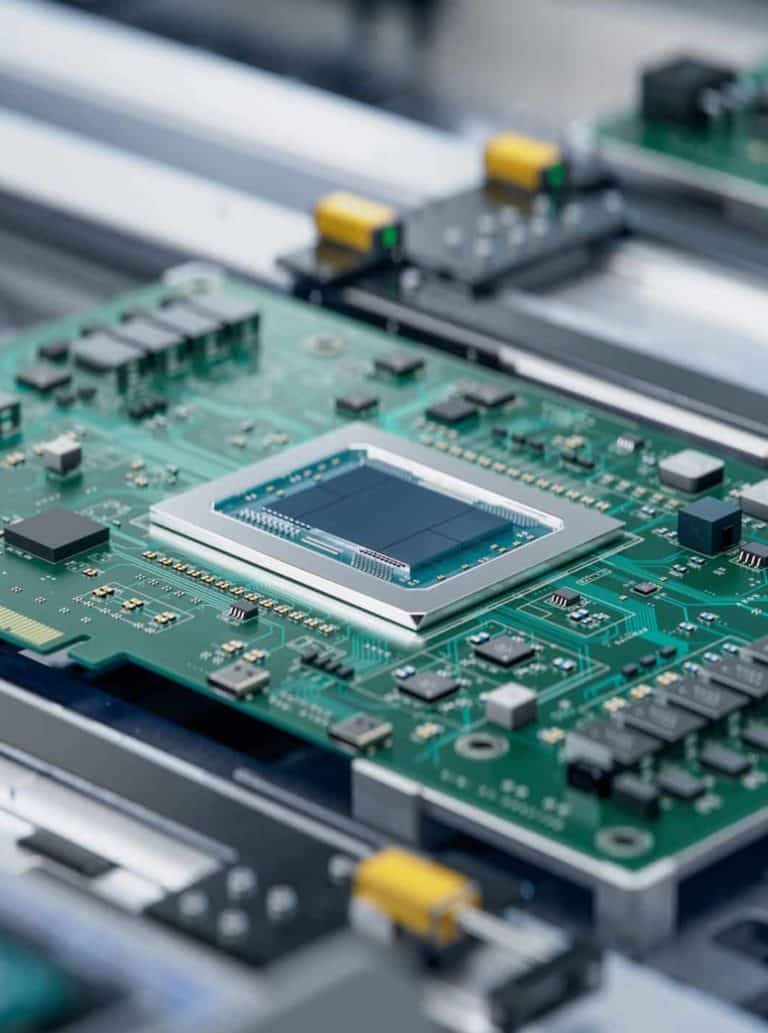

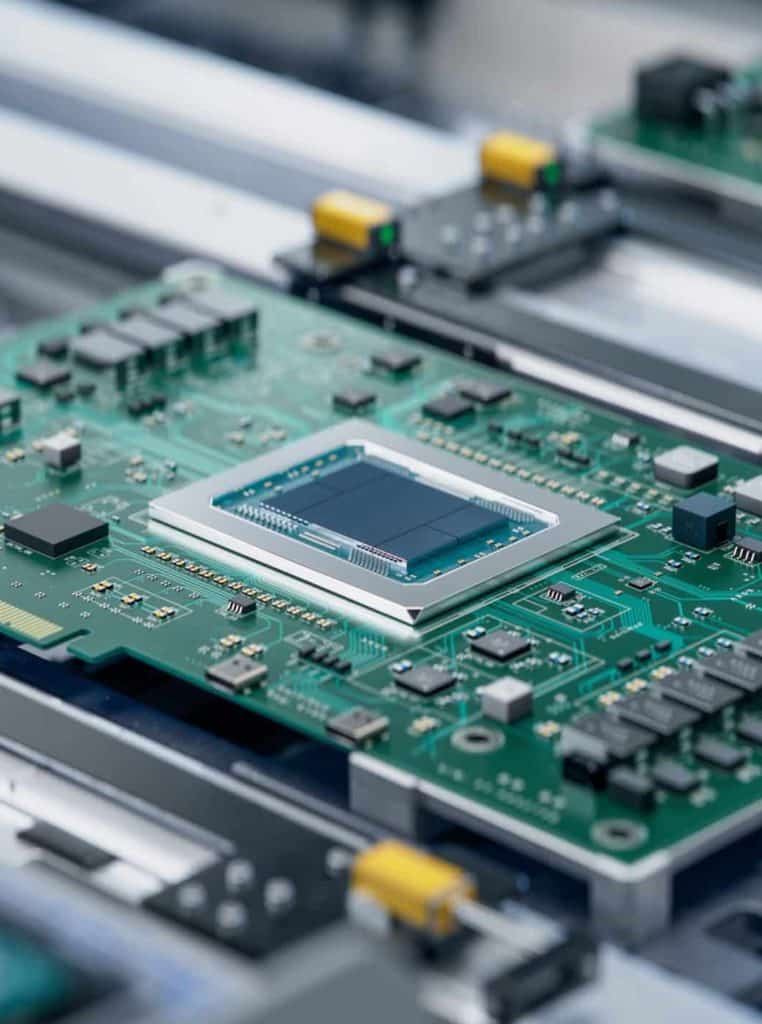

From SMDs to THT and mixed technologies, we handle it all. Whether it’s single-sided or multi-layer HDI boards, we seamlessly integrate every component for superior electrical performance. From prototype to full-scale production, we ensure your project runs with the accuracy it deserves.

Types of PCBs We Specialize In:

- Rigid-Flex PCBs: Combining the best of rigid and flexible circuits, ideal for dynamic applications.

- Single-Sided PCBs: Cost-effective solutions for straightforward designs.

- Flex PCBs: Great for compact, bendable designs where space is at a premium.

- Double-sided PCBs: Increased circuit density for more complex designs.

- Rigid PCBs: Durable and reliable for long-lasting applications.

- Multilayer PCBs: Ideal for sophisticated devices requiring multiple layers of connectivity.