What you need for Circuit Board Repair?

A circuit board is the foundation upon which an electronic device is built. No electronic gadget can perform its functions without a properly functioning circuit board. These boards, made up of interconnected parts to pass signals across the board for optimal functioning of the device in which they are inserted, can also malfunction. After all, these are complex electrical components. If the circuit board does not function appropriately, performing a circuit board repair procedure is critical to determine whether it can be fixed. Timely repairs of minor issues can prolong the life of the board, making the repair vital.

Fundamentals of Circuit Board Repair

Before starting repairing circuit boards, it is essential to be familiar with the basics of what it entails by learning how to repair circuit board. It is a complex and intricate process that involves multiple steps, from troubleshooting to implementing solutions. Those looking to repair circuit boards must be trained in the proper procedures. However, before we delve deeper into the proper processes, let’s understand some fundamentals.

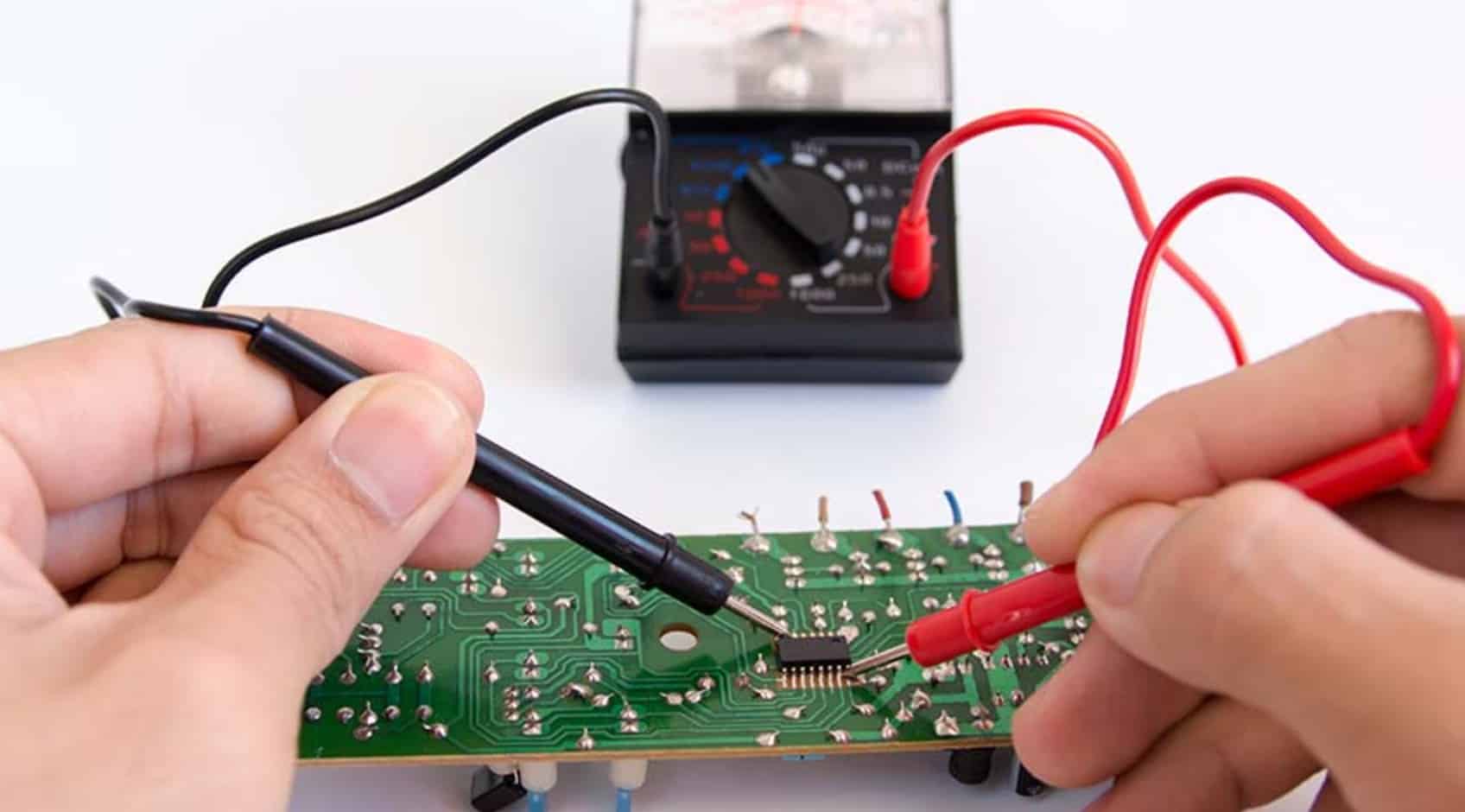

- How to Identify Problems: The foremost thing to learn about circuit board repair is identifying the issue. There can be various reasons behind the malfunctioning of a circuit board. Detecting the exact cause includes conducting a visual inspection to check for any loosened or burnt connections. This step also helps identify any signs of corrosion and prevent the various parts, such as multimeters, to identify issues.

- Learning Proper Soldering: Soldering is vital to repair circuit boards. Developing proper skills in it is essential before starting repairs to avoid errors.

- Maintaining Records: Whenever conducting repair work, it is vital to take detailed records and keep them safely. This makes the process efficient for future errors or when technicians repeatedly run into the same issues.

- Observing Safe Practices: When conducting electronic circuit board repair or PCB repair, it is essential to practice appropriate safety practices. These include wearing safety gear, disconnecting devices from power sources, and conducting careful repairs.

- Quality Checks: Once the repair is complete, it is essential to run quality assurance testing procedures to verify how well the repair has been conducted. If the issue continues, you may have to rethink the repair process or modify the fixing approach. While testing, check functionality parameters such as voltage, stability, fluctuations, etc.

What you need for Circuit Board Repair

When fixing a circuit board, you need not be familiar with the procedure. You also need to be adequately equipped with the right tools and resources. Appropriate equipment makes detecting faults and fixing faults simpler and more reliable. Here is what you need:

- Magnifying Tools: A magnifying glass or lamp is vital when repairing a circuit board. This is because a circuit board is composed of numerous tiny components. Getting a clear vision of the parts during repair is essential for precision.

- Cleaning Resources: Having cleaning materials such as swabs, brushes, and isopropyl alcohol handy is essential. These resources are necessary to clean up dirty bits, dust, contaminants, residue, etc, from the boards, which might be harming their functionality.

- Replacement Parts: A reserve of replacement components or circuit board parts is also important. While not every component can be replaced and fixed, certain parts, like capacitors, resistors, etc, can be changed to repair circuit boards.

- Soldering Equipment: A lot of ‘how to repair circuit boards’ has to do with soldering. Similarly, it also contains a lot of desoldering, necessitating having the appropriate tools and materials for both procedures. Choose high-quality soldering iron and solder (select from leaded or non-lead variants based on the circuit board’s needs). Similarly, choose high-quality desoldering wick, solder sucks, and pumps to help reverse the process.

The process of Fixing Circuit Board

The process of fixing a circuit board is pretty comprehensive, consisting of various procedures, including troubleshooting, diagnosis, and correcting the issues. It is also essential to remember that the techniques for electronic circuit board repair and printed circuit board repair can be slightly different in some respects, so it is necessary to utilize the particular methods suited for the particular kind. The following procedures must be followed for appropriate fixing of circuit boards.

Checking and Analysis: The first step to repairing circuit boards is to inspect the board physically to identify any signs of physical damage in any form. If needed, use magnifying equipment to inspect the minute parts and details of the circuit board for any cracks. While studying, also be careful about checking for previous repairs.

Troubleshooting: If upon physical examination, you do not find any faults, or even if you have seen certain issues, the next step in electronic circuit board repair, as well as printed circuit board repair, is to conduct diagnosis and troubleshooting to find the other problems which are not physically apparent. This helps in finding which parts are malfunctioning or have failed.

Separating Soldered Parts: If the repair is at a part that is soldered or is obstructed by soldered parts, it is essential to desolder these components. This will allow you to look at each element properly and perform the repairs as needed. A vital component for repairing circuit boards is knowing how to solder and desolder various components to fix the issues.

Part Replacements: For any parts that are faulty or damaged, the next step is to replace them with new parts in perfect working condition. To do so:

- Remove the damaged pieces, clear the place where they were attached, and place the new parts in place of them.

- Solder the new parts in place and reassemble.

- While replacing the faulty components, check that the new parts are correctly oriented and are correct in configuration for the needs of the particular device.

Testing the circuit board: Once the repairs have been completed, checking the circuit board’s functionality is essential. For this, try to bring it back to its regular usage, check for various functionalities, and observe to see if there are any issues with the circuit board’s normal performance. Be careful to keep if there is any sparking between the components.

Modify and Fix:

- During testing, check for any faults and note them down.

- After the testing, go back to repair the circuit board by fixing the prevailing issues.

- If an issue is unresolved, take a different approach to improving it or look for a more experienced expert.

- Try other tried and tested processes to arrive at a proper outcome.

The processes for repairing circuit boards are particular and require a keen sense and steady hand. A minor shake of the hand can cause the system to run into irreparable damage. As such, you must know your capability when undertaking such a procedure. If you are new to repairing circuit boards, take your time and polish your skills by practicing to ensure optimal circuit repairs. A malfunctioning circuit board can cause the entire device to fail. Ensuring a broken circuit board is repaired as soon as possible to keep electronic devices healthy is necessary.