What is the Difference between LTCC and HTCC ceramic?

LTCC and HTCC

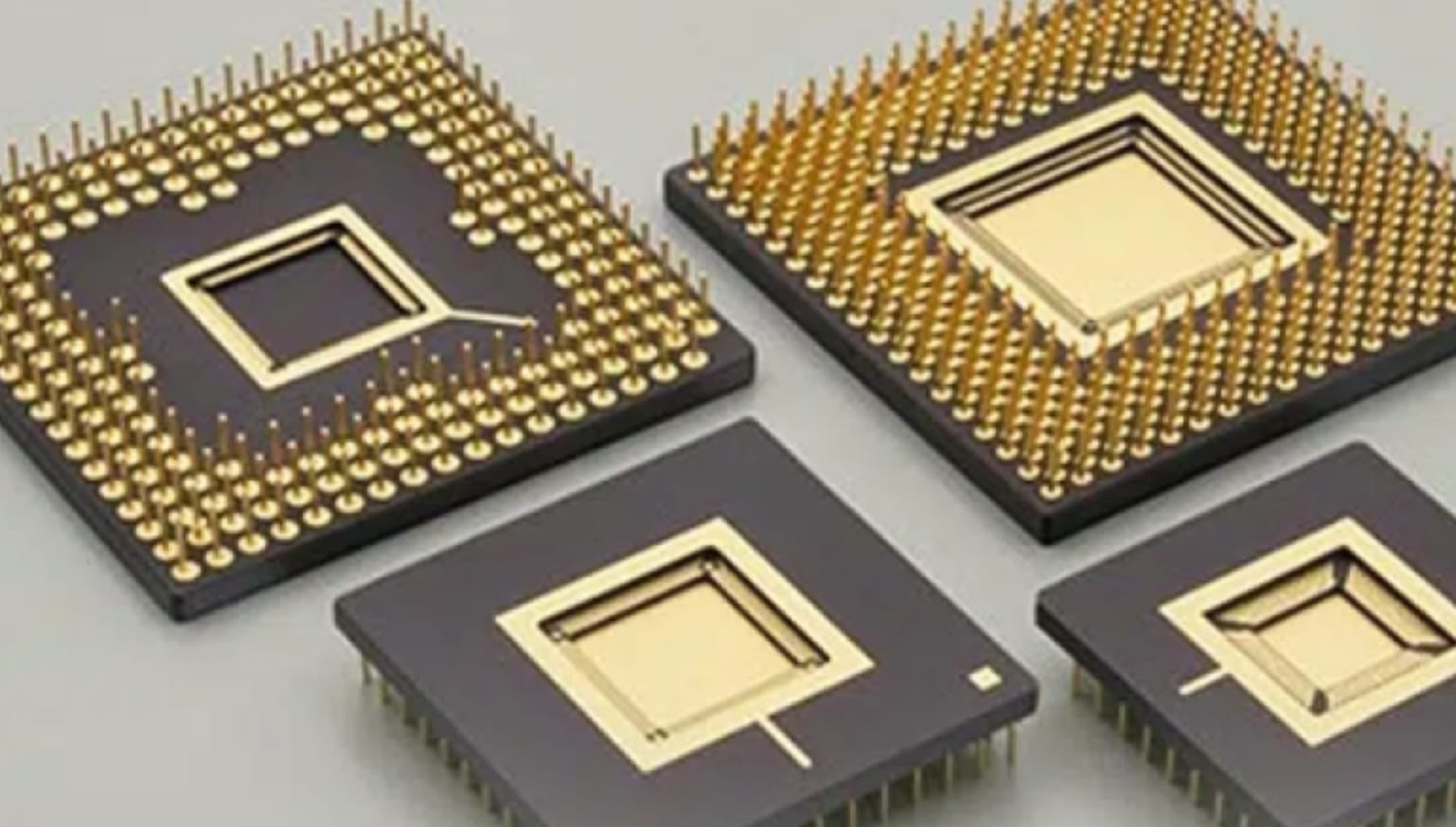

The ceramics packaging methods known as LTCC and HTCC are widely used in the electronics market. The Low-Temperature Co-Fired Ceramic and High-Temperature Co-Fired Ceramic methodologies offer specific advantages, dictating which way should be used for which application. LTCC is vital for incorporating passive elements such as capacitors and entails co-firing ceramic layers at temperatures below 1,000 degrees Celsius. Alternatively, HTCC allows the integration of elements with greater melting points by permitting co-firing at temperatures above 1,000°C. A combination of the two techniques is used for applications demanding compactness, efficiency, and temperature regulation.

Materials for Composition

LTCC Ceramics

LTCC Ceramics are usually made of a blend of natural binders and crushed glass as well as ceramic materials that have been coarsely crushed. The combination of the ingredients enables the creation of an adaptable, sheet-like material known as “green tape.” After that, the green tape is carefully piled and shaped to create many different layers. A robust, multiple-layered ceramic framework is produced when natural binders are burned away, and the glass-ceramic substance compacts through the co-firing procedure.

HTCC Ceramics

Since HTCC is made for purposes necessitating more powerful temperatures, it frequently uses ceramics featuring greater melting temperatures. Because of its superior heat conductivity and durability at high temperatures, alumina, or aluminum oxide, is a substance that is commonly used in HTCC ceramics composition. Similar to LTCC, numerous layers of the ceramic substance are co-fired in HTCC. This process is focused on delivering improved thermal efficiency and endurance, making it perfect for uses needing extreme resistance to high temperatures.

LTCC and HTCC techniques utilize the co-firing method to generate merged ceramic elements that address the need for highly efficient, downsized electronic elements in various applications, such as healthcare, aerospace, and telecommunications

Differences between LTCC and HTCC Ceramic

Temperatures of Firing:

LTCC: In most cases, the co-firing procedure for LTCC occurs at temperatures under 1,000 degrees Celsius. Using glass-ceramic substances, which may harden at reduced firing temperature levels, makes it possible to get desired outcomes at minimal temperatures.

HTCC: HTCC, on the other hand, entails co-firing at heat above 1,000 degrees Celsius. Because of this greater temperature spectrum, substances with greater melting temperatures, such as alumina, may be used.

Materials:

LTCC: LTCC is usually made up of some combination of natural compounds along with powdered glass and ceramic materials ground roughly. The glass-ceramic substance combines characteristics appropriate for co-firing at low temperatures.

HTCC: High melting point ceramics, such as alumina, are frequently used in HTCC. Using alumina for HTCC compositions enhances durability and thermal transfer at high temperatures

Applications:

LTCC: LTCC works effectively in situations that call for the creation of multiple-layered frameworks with embedded elements that are passive. The applications of these kinds of ceramics are typically found in small gadgets, radio frequency parts, and miniature electronics.

HTCC: HTCC is the material of choice for uses that call for endurance and consistency at more extreme temperatures. It is widely used in industries including intense-power electronic devices, sensors, and some aerospace-related parts that need to be resistant to elevated temperatures and adverse circumstances.

Pros and Cons of LTCC and HTCC Ceramic

Pros of LTCC

Downsizing and Combining: Due to LTCC, it is possible to integrate several functionalities into a small form and miniaturize electronics. In settings where area is a crucial component, this is beneficial.

Multiple-layered Structures: The integration of elements into complicated, stacked systems is made possible by LTCC. When designing complex electronic systems, this capability comes in handy

Minimal-Heat Processing: Solutions that need the integration of heat-sensitive components or substances can benefit from LTCC due to the reduced firing temperatures throughout the co-firing procedure.

Utilizing Radio Frequency: Because of its capacity to form complex structures and preserve strong electrical characteristics at elevated frequency ranges, LTCC is a suitable fit for RF and microwave technologies

Economic Efficiency: Under some circumstances, LTCC could become more affordable. These include purposes that call for combined passive features as well as compactness.

Cons of LTCC

Weak Capability for Withstanding High Temperatures: Functions that must withstand high temperatures might not fit LTCC well. There can be restrictions on the components’ capacity to withstand extreme temperatures.

Specific Material Restrictions: Compared to resources utilized in high-temperature ceramics, LTCC components cannot exhibit the same degree of mechanical durability and thermal conductive properties

Manufacturing Intricacy: Producing LTCC parts may be challenging, particularly for sophisticated designs. Costlier production processes might result from this intricacy, rendering them an economic challenge.

Pros of HTCC

Maximum Temperature Consistency: HTCC can be used in tough locations or systems where operating temperatures must be raised because of its ability to tolerate excessive temperatures.

Superior Thermal Conduction: Heat conduction is quite good with HTCC, particularly when alumina-based compounds are used. Uses where efficient heat dispersion is essential would benefit from this feature.

Mechanical Potency: Unlike LTCC, HTCC ceramics often possess better mechanical strengths, offering longevity and resilience to stress from mechanical contact.

Adaptability in Use: Because of its adaptability, HTCC is used in several sectors, such as electrical devices, aviation, and automobiles, where endurance to high temperatures is crucial.

Cons of HTCC

Costs: Given the inclusion of substances with higher melting temperatures and high-temperature fabrication requirements, HTCC parts can be more costly to produce than LTCC parts.

Restricted Downsizing: Although HTCC might offer steadiness at elevated temperatures, its utility in some electrical systems could be limited as it might not be as suitable for downsizing.

Handling Difficulties: Managing particular substances and attaining precise control during manufacturing may be difficult because of the greater temperatures used in HTCC production.

LTCC and HTCC are both unique and suitable for distinctive applications. According to their particular properties, various components and electronics manufacturers must assess which method is suitable to attain desired outcomes. Through this, optimal functioning is ensured.