What is Rapid PCB Prototyping? – Meaning, Advantages & Key Application

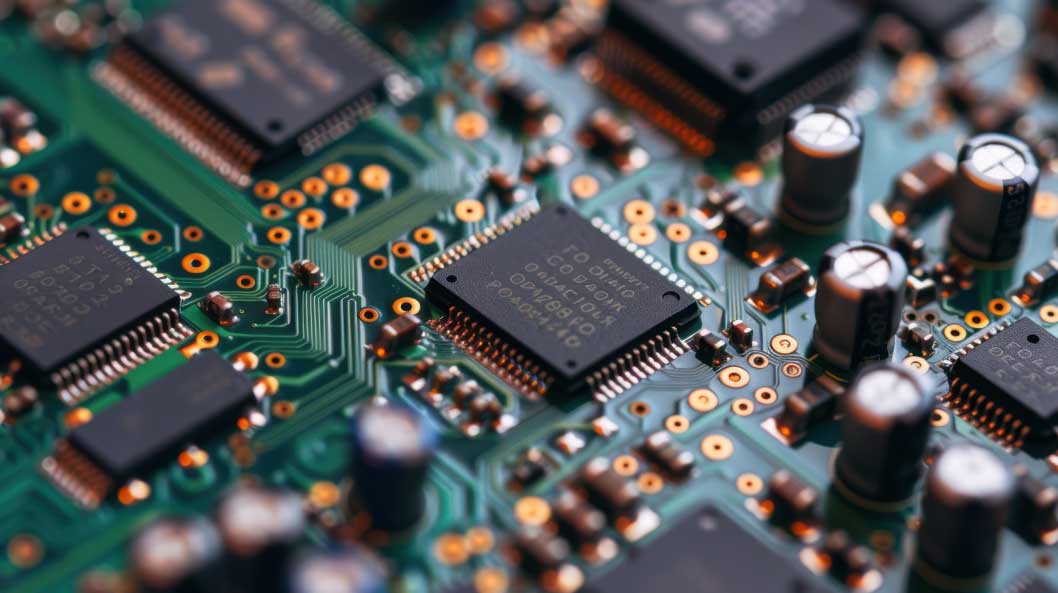

The world of electronics design is evolving at breakneck speed, with companies constantly striving to outdo one another in terms of innovation, functionality, and time to market. In this dynamic environment, rapid PCB (Printed Circuit Board) prototyping has become a crucial element in the design process, helping engineers and developers turn their ideas into tangible products faster than ever. The growing need for quick turnaround times, lower costs, and the ability to iterate designs rapidly has made rapid PCB prototyping a game-changer in the industry.

Whether you’re an electronics hobbyist, an engineering startup, or a seasoned player in the tech field, understanding the nuances of rapid PCB prototyping can greatly influence your design process. From reducing errors to shortening product development cycles, rapid prototyping of PCBs is revolutionising how ideas are brought to life.

Understanding Rapid PCB Prototyping

Rapid PCB prototyping is the process of quickly creating physical prototypes of printed circuit boards from digital designs. This approach allows designers to test, validate, and refine their designs before moving on to mass production. Unlike traditional prototyping, which can take weeks, rapid PCB prototyping leverages advanced manufacturing technologies like CNC milling, laser cutting, and 3D printing to deliver prototypes within days or even hours.

The primary goal of rapid prototyping is to provide a cost-effective and efficient way to validate design concepts early in the product development cycle. By doing so, it helps identify design flaws, reduces the risk of costly errors, and ensures that the final product meets all necessary specifications and quality standards.

Rapid PCB Prototyping vs. Standard PCB Prototyping

When comparing rapid PCB prototyping to standard PCB prototyping, the most striking difference lies in the speed and efficiency of the process.

Rapid prototyping is all about quick turnaround—think days instead of weeks. It’s designed to get your prototype in hand as soon as possible, which is a massive advantage when you’re in the early stages of product development or working against tight deadlines. Standard PCB prototyping, on the other hand, follows a more traditional approach, with longer lead times due to more complex setup processes and the need for extensive tooling. This can slow down the design validation phase, making it harder to spot and fix issues quickly.

Another key difference is the level of flexibility.

Rapid PCB prototyping allows for frequent design iterations without significant cost implications, making it easier for engineers to tweak and optimise their designs on the fly. This flexibility can be particularly valuable for startups and smaller companies that need to pivot quickly based on market feedback or design challenges. In contrast, standard prototyping can be more rigid, often involving higher setup costs, especially for small production runs. This can make changes more expensive and time-consuming, reducing the overall agility of the development process.

Simply put, rapid prototyping is about speed, adaptability, and getting it right without the long wait, while standard prototyping is better suited for projects that are past the initial design phase and ready for larger-scale production.

Key Aspects of Rapid PCB Prototyping

Speed and Efficiency: The cornerstone of rapid PCB prototyping is speed. Advanced machinery and automation drastically reduce the time required to produce prototypes, allowing for quicker iterations and feedback loops.

Flexibility in Design: Rapid prototyping supports a wide range of design complexities, from simple single-layer boards to multi-layer, high-density interconnect (HDI) boards. This versatility allows engineers to experiment with various design layouts and components without being restricted by manufacturing limitations.

Cost-Effectiveness: Traditional PCB prototyping often involves high setup costs, especially for small batches. Rapid prototyping, however, eliminates much of this overhead, making it more affordable, especially for startups and small businesses looking to test their designs.

Quality and Accuracy: Despite the quick turnaround, modern prototyping techniques ensure high levels of precision and quality. Prototypes are made with nearly the same materials and processes as the final product, ensuring that any performance or design issues can be accurately assessed.

Advantages of Rapid PCB Prototyping

Reduced Development Time: By enabling quick testing and iteration, rapid PCB prototyping significantly cuts down the overall product development time, helping companies get their products to market faster.

Improved Design Validation: Early detection of design flaws helps refine the product before full-scale production, reducing costly revisions later in the process.

Enhanced Innovation: Designers can experiment with different designs and materials without worrying about the high costs typically associated with prototyping, encouraging greater creativity and innovation.

Customer Satisfaction: Faster prototyping means quicker feedback and updates, which can be critical in meeting customer demands and ensuring a final product that truly meets their needs.

Key Applications of Rapid PCB Prototyping

Consumer Electronics: Essential for the fast-paced development of smartphones, tablets, wearables, and smart home devices, enabling quick iterations and faster market entry.

Automotive Industry: Facilitates testing and refining of electronic systems like engine control, navigation, and ADAS, ensuring safety and functionality before production.

Medical Devices: Supports the development of circuit boards for diagnostic and monitoring equipment, enhancing precision and compliance with regulatory standards.

Aerospace and Defense: Used for testing circuit boards in communication, navigation, and avionics systems under extreme conditions, meeting strict performance requirements.

Industrial Automation and Robotics: Critical for designing control systems, sensors, and power solutions in robotics and automated processes, improving efficiency and reducing downtime.

Telecommunications: Aids in developing circuit boards for routers, switches, and modems, ensuring products meet the latest standards in speed, reliability, and efficiency.

Renewable Energy: Used in solar inverters, wind turbines, and energy storage systems, helping validate designs for efficient and sustainable energy solutions.

Wearable Technology: Helps create compact and efficient PCBs for fitness trackers, smartwatches, and other devices, optimising functionality in limited spaces.

What to Look for in an Ideal Rapid PCB Prototyping Partner?

Choosing the right rapid PCB prototyping partner is vital for the success of your project. Here are key factors to consider:

- Turnaround Time: Look for a provider that offers quick delivery without compromising on quality. Fast turnaround times can make or break tight project deadlines.

- Experience and Expertise: Partner with a company that has proven experience in handling complex designs and offers technical support to help troubleshoot any design issues.

- Quality Assurance: Ensure your chosen partner has stringent quality control processes to ensure the prototypes meet your specifications.

- Customization Options: The ability to customise prototypes according to your specific requirements, including different materials, board thicknesses, and surface finishes, is essential.

- Cost Transparency: Hidden costs can derail your budget. Choose a partner who offers clear and upfront pricing.

Wrapping it up

Rapid PCB prototyping is transforming the way electronics are designed, tested, and brought to market. Its speed, flexibility, and cost-effectiveness make it an invaluable tool for innovators looking to stay ahead of the curve. Whether you’re developing cutting-edge consumer electronics, medical devices, or industrial automation solutions, rapid prototyping ensures that your designs are perfected before hitting full-scale production.

Ready to take your PCB prototyping to the next level? Partner with Absolute PCB Assembly for fast, reliable, and high-quality prototyping services that will keep your projects on track. Contact us today to get started and see how we can help bring your ideas to life!