What Is Kapton PCB?

PCB is one of the innovations that a storm has taken up the world. It is getting its uses and applications in many sectors. And the future holds pretty brightly, given the organizations and industries are having pretty positive experiences.

Printed circuit boards are ubiquitous in today’s world. They’re in cellphones, iPads, laptops, radios, and a variety of other digital equipment. Yet, even though they encircle us, some of us may have little knowledge of PCBs.

PCBs are being used in practically anything electrical, whether you realize it or not. Today’s article will discuss one of the prominent innovations of PCB, Kapton PCB, and its fundamentals.

What is Kapton?

Kapton is a polyimide, according to a broad definition. To get a more vital insight into Kapton, you must first comprehend polyimide. Polyamide is generated when dianhydride and amine group monomers combine under compressed circumstances. In polyimide, a nitrogen covalent link exists between two carbonyl groups. The two connections of the nitrogen and carbonyl unit are termed the imine unit. Polyimide is used in many applications due to its high strength and toughness, broad temperature spectrum, and chemical inertness.

Because Kapton is a high conductivity polyimide, it is commonly utilized in electronic equipment. The primary aim of Kapton is to regulate the temperature in electronics equipment. Whenever we need a slim, lighter weight, and consistent heater, Kapton is a wise option. Automotive interior warming, wind turbines, and temperature control in aerospace all need this lightweight, homogeneous nigh temperature capability. As a result, Kapton’s polyimide conductivity film can help all of them. Kapton flexible PCB is no doubt getting its appreciation for a good reason.

What are the characteristics of Kapton?

Exceptionally high and low-temperature variations are no problem for Kapton. Kapton has exceptional mechanical, electronic, and physical capabilities throughout a range of temperatures of -452 to 752 degrees Fahrenheit. Because Kapton is an excellent resister & insulator, it is a powerful choice for high-demand sectors like electric applications and aircraft. Some of Kapton’s advanced features are listed below:

- It is quite effective.

- It is highly stable across a wide temperature range.

- It can withstand extremes in both heat and cold.

- It has good mechanical, physical, and electrical qualities, making it an excellent choice for high-stress applications.

- It is suitable for a wide range of applications.

- It is very resistant to radiation and chemicals.

- It ensures that labels are accurate.

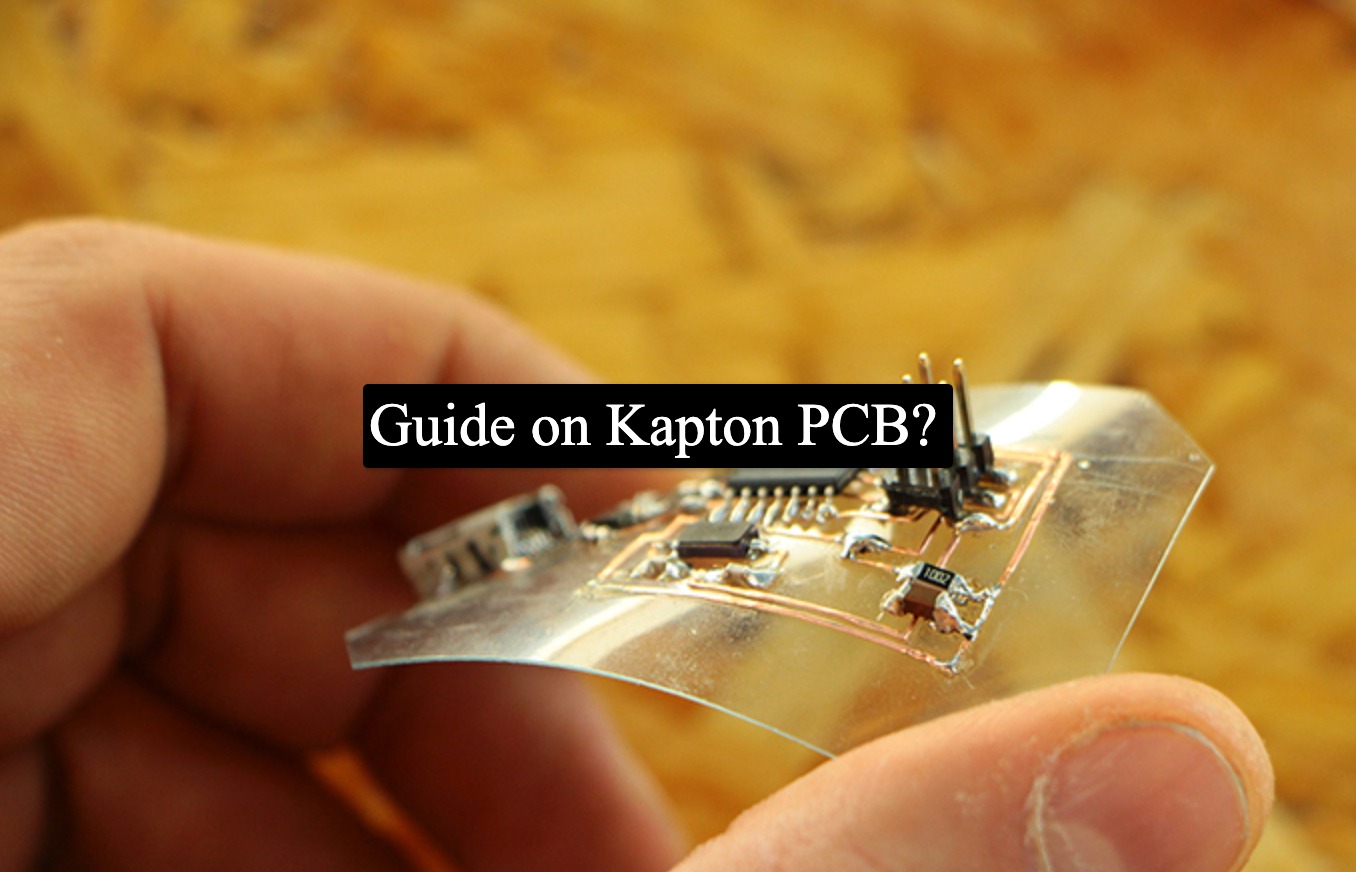

What is Kapton PCB?

Printed circuit boards (PCBs) are dynamically supported and connected electronic parts using forming processes such as tracks and trails coated with copper. Printed circuit boards, in a nutshell, are used to enable paths in digital equipment. Printed circuit boards are found in every electronic device since they are the means through which information is transferred within the gadget.

After mastering simple printed circuits, you’ll be ready for versatile printed circuit boards. You can create your own interface requirements, and depending on them, a flexible printed circuit can be created to use a polyamide such as Kapton as a raw product.

Excessive heat is the primary cause for the use of Kapton in electrical components. As we all know, excessive heat frequently occurs in the production of electronic gadgets and printed circuit boards. Temperatures can reach over 400 degrees Fahrenheit. Kapton is a fire-resistant material that can withstand temperatures of up to 700 degrees Fahrenheit without affecting the label’s look or performance. In addition, Kapton is a robust polyimide polymer that can tolerate harsh circumstances to provide consistent circuit board labeling.

Single-layer to double-layer adaptable PCBs is available. However, every sort of printed circuit board will have a polyimide Kapton base coat. Kapton flexible PCB is no doubt one of the greatest innovations.

What are the advantages of using Kapton PCB?

Kapton flexible PCB comes with many advantages. Kapton is a conducting polyamide with high conductivity. Its primary role is to regulate the amount of heat in the gadget. Aerospace, wind turbines, and automobiles are some of their most popular uses. You may get many PCB boards using Kapton and polyamide PCB.

Kapton printing circuits are used in a variety of applications. The Kapton circuit boards’ versatility is a need for numerous electrical equipment. Below are some of the benefits of Kapton PCBs:

- Kapton printed boards are developed to fulfill greater and lesser complexity mountain designs while also increasing flexibility. Kapton aids in the reduction of setup time while also increasing reliability. Kapton printing circuit boards can only help to increase miniaturization and signal transmission in electronics equipment.

- The circuit’s base has a wide polyimide layer with a copper layer. The answer ranges from single system Kapton circuits to multilayered or 3-dimensional Kapton print circuitry for lightweight and compact circuitry or compact and complicated devices. Perpetuating the circuit’s foundation element can provide increased structural stiffness and durability. The circuit’s power would be improved as a result of this.

- The Kapton circuit, as its name implies, is flexible, allowing it to stretch, slide, and twisting effect. As a result, the conductance would not be harmed as a result of the mobility.

- Kapton circuits offer outstanding electric efficiency due to their versatility. Because of the low dielectric constant, there is a nice flow of electrical impulses. Because of their superior thermal qualities, parts can be cooled quickly after being exposed to heat. Furthermore, due to the greater glass transitioning, parts can perform very effectively over a wide range of temperatures.

- Another significant benefit of adopting Kapton printed circuit boards is that they can be made smaller, which is necessary for many industries. Many electronic products, such as tablets, laptops, military hardware, aerospace, PDAs, passive components, digital technologies, cellular phones, and many more industries, demand thinner, and lighter sizes and weights.

Why do we rely on Kapton Polymide in our PCB?

Kapton polyimide circuit board boards are developed for various uses, so you must understand once you can have them and when you might ignore them. The objective of developing Kapton polyimide circuitry was to increase the circuit’s durability and functionality while reducing its shape and volume. Below are some of the grounds why we choose Kapton printed circuitry for normal circuits:

- Thermal power consistency

Kapton flexible PCB is the epitome of thermal power consistency. Even though we already know it, polyimide material has great durability and heat resistance and is more accurate than any other substance. This great property of polyimide substance aids in handling electronic component temperature challenges. Digital components can operate at temperatures as low as 260 degrees Fahrenheit thanks to Kapton polyimide. Furthermore, the solid thermal power constancy protects the gadgets from harm when operating and fixing.

- Greater adaptability

It’s no rocket science that Kapton PCB comes with great flexibility. Another significant advantage of Kapton polyimide circuitry is its exceptional mobility and resilience. Kapton print boards can readily be handled and bent as a result of this characteristic. This is the ideal combination of adaptability and stiffness in a printed circuit board, which is something that typical boards lack.

- Extremely durable

Kapton PCB has stronger resistance to heat and many other substances, making it a long-lasting material. Managing great physical stress necessitates this capacity.

Final thoughts

Kapton PCBs are more energy-efficient due to their versatility. Because of the continuous dielectric, electrical impulses flow freely. Due to the wonderful thermal qualities, parts may swiftly cool down after being exposed to heat. Furthermore, due to the high transitions of the glass, the parts can perform well in extreme temperatures.

Another significant benefit of adopting Kapton flexible PCB is that the area of the circuitry required for most purposes can be reduced. As a result, many electronic products, such as notebooks, laptops, military hardware, aircraft, PDAs, passive components, electronic devices, cellular phones, and many more industries, demand a small size and low cost.

Also Read:-