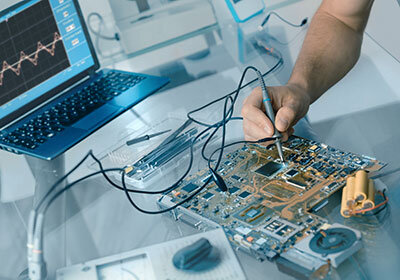

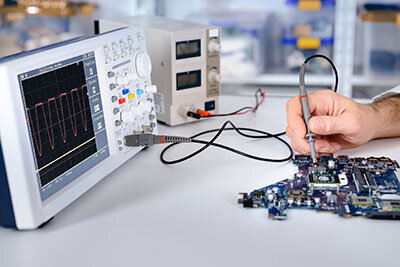

Comprehensive PCB Testing for Performance and Reliability

Our Test Engineering department is staffed with experienced electrical engineers and technicians who excel at working with customers to develop methodologies and design fixtures to reduce overall manufacturing costs, improve production yields, identify failures early, support root cause analysis, and assist customers with DFT (Design For Test) analysis. Our extensive testing capabilities are more than enough for any need. Depending on product design, component selection, production procedure and batch volume, we aim to draw together a testing strategy that delivers the highest product quality.

We can help. Our team of expert is on hand to answer your questions

Functional test is used as a final manufacturing step. It provides a pass/fail determination on finished PCBs before they are shipped. The purpose of this testing method in manufacturing is to validate that product hardware is free of defects that could, otherwise, adversely affect the product’s correct functioning in a system application.

In short, it helps to verify a PCB’s functionality and its behavior. It is important to emphasize that the requirements of a functional test, its development, and procedures vary widely from PCB to PCB and system to system

Absolute electronics is Rated 5.0 based on 3 reviews.

Address :

Absolute Electronics Services LLC

330 W Fay Ave

Addison, IL – 60101

2026 Absolute Electronics Services, All Rights Reserved