Turn your concept into a reality

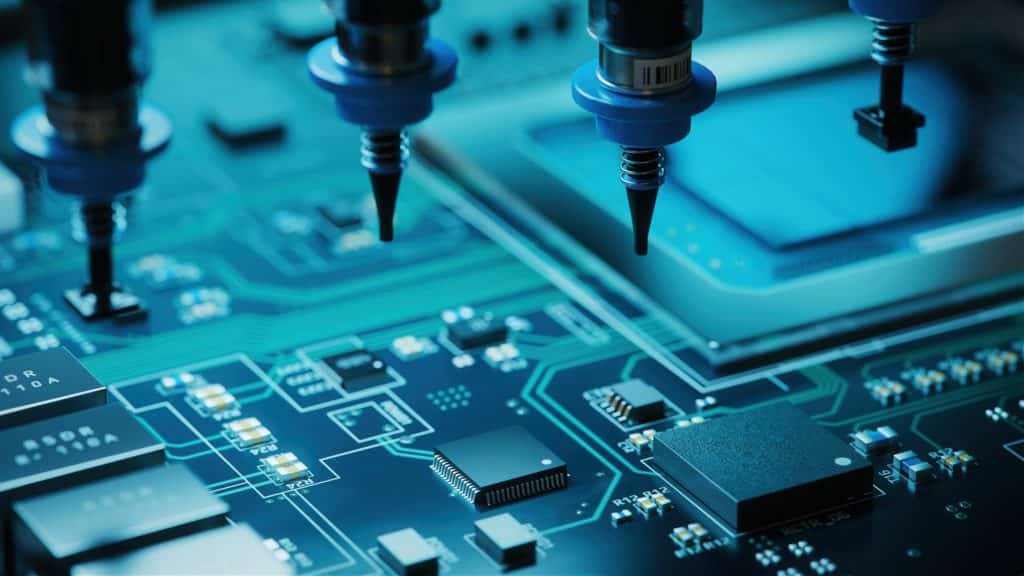

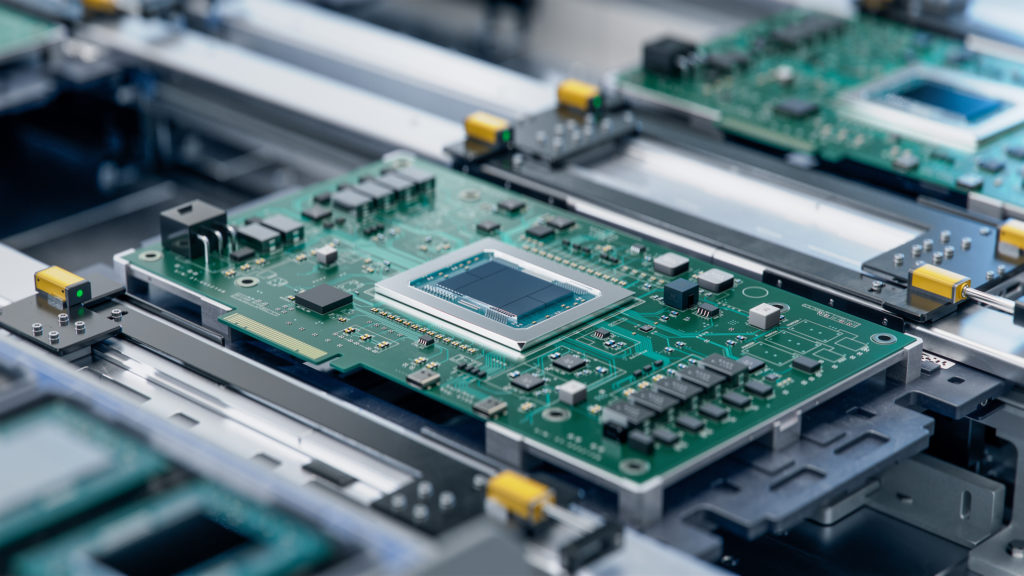

Because of the oscillating work role of PCB circuits, electronic devices and gadgets emerge. Following World War II, an Austrian engineer called Paul Eisler was the first to create PCBs. His unique techniques for PCB etching, different connection routing technologies, and electrical conductors in boards have been in use for decades.

PCBs are the foundation of all significant electronic devices. These innovations may get found in almost every type of computational device. For the uninformed, a PCB is a circuit board that transmits electrical impulses via electronics to meet the electrical and mechanical circuit needs. In a nutshell, PCBs direct the flow of electricity, allowing your electronics to function.

Before beginning PCB design, circuit board manufacturers should visit a PC board workshop and meet with fabricators in person to discuss their PCB production systems. It aids in preventing designers from transmitting any needless mistakes throughout the design stage. Producers transfer the layout into a format that their circuit board manufacturers accept once the PCB design gets authorized for manufacturing.

PCB increases the long-term endurance of gadgets and devices, resulting in extreme superior efficiency for a long period. Durability does not guarantee that the PCBA will not get destroyed. It will cause damage. However, the period between hits is longer than intended.

Absolute Electronics Services, as a PCB manufacturing organization, strives to offer PCBAs that are very durable. Before certifying it as an authorized product, we perform different stages of examination and thorough analysis. We also provide product testing facilities to other Printed Circuit board manufacturers.

We can help. Our team of expert is on hand to answer your questions

Organizations that develop, analyze, produce, distribute, or provide aftermarket support for electronic components and systems offer electronic manufacturing services (EMS).

Electronics contract manufacturing services differ depending on the provider. You can expect PCB assembly. It is the technique of soldering parts like transistors, capacitors, and electronic components onto a bare board utilizing surface mount technique or through-hole technique. You can transport power and communications between hardware objects using a finished PCB. Because there is more human involvement with the board, through-hole requires more time. The fully functional in-house testing services will get provided by the entire electronics or Printed Circuit Board manufacturer.

You may reap the benefits of manufacturing, technical experts, and manufacturing teams by outsourcing out design. The supplier should accomplish all of this while providing you with paperwork and obtaining regulatory permission.

A PCB component can be tested in a variety of ways by your circuit board manufacturer. Manufacturers provide services ranging from a visual examination to a testing phase. You’ll ensure your item was created to your requirements if you choose for rigorous testing before receiving it.

The innate safety of any electromechanical assembly operations should get considered. Setup management is a technique for ensuring that your product’s functionality and appearance are consistent. The practice of infusing a final assembly with a mucus substance to increase dampness, tremor, shock, and corrosion resistance get known as potting. Heat shrink is a plastic tube that shrinks and fits over the wire. For these operations, a strong electronics manufacturer may employ a specialized assembly process crew.

The goods will get designed, tested, and manufactured by a well-crafty vendor. Manual soldering gets used in the production of cable assemblies. Check to see whether your provider is capable of being crafty. Many of them can also do injection over-molding. It is a method of fabricating a single item out of various materials. During production, the initial material is usually partly screened by succeeding materials. It may be costly to make a mistake with an electrical gadget deployment. When it comes to launching, PCB prototyping might assist you in escaping a frustrating scenario.

Absolute Electronics Services, one of the top PCB manufacturing companies, gets dedicated to the digital realm. The firm’s foremost goal is to diminish the need for continual PCBA maintenance and refurbishment. Even though the world of technology is a large entity made up of many smaller parts, we only work with a tiny segment. PCB manufacturing and assembly is an essential element of a larger entity that may help devices and utilities run well for a long time.

Absolute electronics is Rated 5.0 based on 4 reviews.

Absolute Electronics Services production process for the PCBA is readily identifiable from the other electronic manufacturing companies. They’ve devised a production method that is both adaptable and flexible. PCB assembly manufacturers can react to the needs of the people thanks to this distinctive and adjustable production method. As a result, they may optimize goods and production techniques to meet people’s needs. As a result, AES is one of the companies that offer clients supply chain solutions for the production process:

Apart from that, they concentrate on numerous PCB fast prototype services throughout PCBA production. Cost optimization, technical prototypes, sourcing design, design, and constructability are all included.

There are just two primary elements that have a significant effect on product quality and reliability. The first is a Checkup, and the second is Test. Absolute Electronic Services covers a wide variety of examination and human testing processes to assure the precision and reliability of PCB manufacturing services. Because PCBs are the essential component of electronic technologies and devices, PCB manufacturing and assembly enables us to take the lead in providing long-lasting, elevated goods.

You’ll get your reply if you look at a few before manufacturing data, evaluations, and customer comments. As a PCB assembly manufacturer, we adhered to a strict code of conduct to maintain high PCB efficiency. As a result, we have assembled an optimal team of professionals to carry out great production. We’ve created several unique programs that allow clients to tailor the production process to their individual needs. We allow adjustable lead-time, as quick as 24 hours.

Moreover, before shipping it for delivery to customer, it undergoes a series of examinations and testing to verify its exceptional quality. Our authoritative and friendly salesperson will help you through your order process. Our support engineers are always there to hear from you. From manufacturing to customer support, we believe in excellence and efficiency. Our primary goal is our client’s convenience.

The circuit board gets made by a combination of photos and etching processes. First, the panels get coated with photosensitive film, and then the images in the artwork are printed on these coated panels. The printing is acid-resistant, allowing the unnecessary copper area to be etched away, leaving only the parts that make up the circuit. The etched layers are then laminated together. They are pressed together with resin-coated glass fiber sheets under high pressure and high temperature. When the board cools, the layers get glued together.

In the next step, drill holes. These holes get located using the drilling data in the Gerber file. Some circuits on different layers must be connected, which gets done by through-hole plating. The solder mask is then used as a coating to protect the circuit from solder spatter during the final PCB assembly process.

Of course, a part of the circuit must get exposed to the place that needs to get soldered surface mount chip, connection hole, etc. The circuit board gets finished now and only needs to be processed. It includes cutting circuit boards to size, electrical testing for open and short circuits, and manual visual inspection to ensure high quality.

The firm’s foremost goal is to diminish the need for continual PCBA maintenance and refurbishment. Even though the world of technology is a large entity made up of many smaller parts, we only work with a tiny segment.

Absolute Electronic Services is one of those PCB firms that value essence rather than volume. Although it has only made the best contributions to the world of electronic devices, it has also made contributions from various angles. It is a leading manufacturer of printed circuit board components. Our manufacturing facility is located in Illinois. However, we provide services nationwide.

Absolute Electronic Services is an ISO 9001:2015 certified company.

As a PCB assembly manufacturer, we adhered to a strict code of conduct to maintain high PCB efficiency. Absolute Electronics is devoted to surpassing client expectations. We can customize our manufacturing outlines to meet your funds and time span without decreasing our quality measures.

Since 1995, we have provided high-quality PCB assembly services to numerous companies in a broad spectrum of industries. All our PCBs get produced and inspected using equipment with the latest technology to ensure products meet the high degree of quality.

Address :

Absolute Electronics Services LLC

330 W Fay Ave

Addison, IL – 60101

2025 Absolute Electronics Services, All Rights Reserved