How to Choose the Right PCB Resistor

An electronic element called a PCB resistor is utilized in circuits to control the amount of electrical charge that flows through a circuit. They aid in controlling the current and voltage of the circuits and are placed directly into PCBs. Several types of resistors exist, including networks, chip resistors, and surface-mount resistors (SMD). They are available in various resistance levels and voltage ratings to accommodate a range of circuit needs. To maintain correct electronic equipment and systems performance, PCB resistors are essential for splitting voltage, regulating current flow, and changing signal outputs.

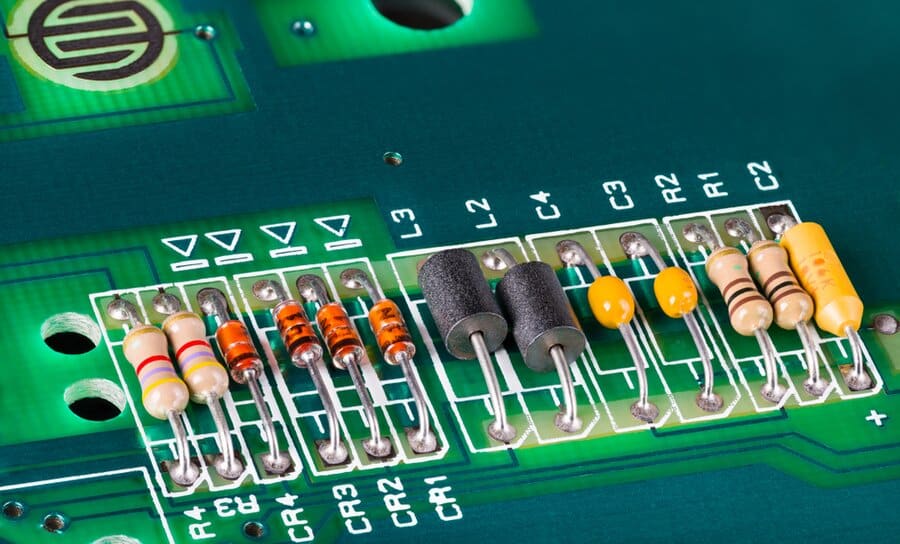

Types of PCB Resistors

There are several different types of PCB resistors available on the market. Each of them has varied applications and is useful for different purposes. Depending upon the intended usage of the product wherein they are placed, the PCB resistors can be chosen from the following types:

- Through-Hole Resistors: A through-hole resistor consists of leads connected to the printed circuit board from the reverse side after being pushed into slots within the circuit board. They work well with circuitry that needs to handle more power since they come in a range of resistance levels and energy ratings.

- Chip Resistors: A particular type of SMD resistors, known as chip resistors, are distinguished by their tiny size and microchip-like form. These have become popular as they are compact, making them perfect for printed circuit boards with many elements and little room.

- Thick Film Resistors: These types of pcb resistors are created by putting a resistant substance upon the surface of a printed circuit board. These are often used in electrical gadgets and provide exceptional stability, dependability, and accuracy.

- Surface-Mount Resistors (SMD): SMD-type resistors are tiny resistance devices primarily used to assemble printed circuit boards using surface-mount technology (SMT). They are shaped like chips, rectangles, or cylindrical forms. SMD resistors are tiny and simple to assemble since they are connected straight to the PCB’s substrate.

- Thin Film Resistors: A slim layer of resistant materials is deposited upon the printed circuit board to create thin film resistors. Compared with thick film resistors, these offer greater flexibility and thermal support, qualifying them for precision operations.

- Network Resistor: These can be considered collections of many resistors in one package. Network resistors enable circuit builders to streamline circuits and conserve space by combining several resistive components into a single unit.

- Variable Resistors: The electrical resistance for this type of resistor may be adjusted manually. Rheostats, a variety of variable resistors, are two-terminal gadgets primarily used to control current, whereas Potentiometers, another kind of variable resistors, are three-terminal gadgets utilized to change voltages

Purpose of a PCB Resistor

The diverse variety of printed circuit board resistors indicated that these elements can be utilized for a variety of purposes across varied gadgets. Irrespective of the kind of usage they fulfill, these are highly integral parts of a gadget’s circuitry and must be designed and utilized as such. The most common purposes that the different types of these pcbs serve include the following:

Surface-Setting Resistors: The resistors in this category are perfect for packed printed circuit boards due to their small footprint, which is why surface-mount technology applications utilize them so frequently. Precision applications benefit significantly from their high space efficiency, which allows for the downsizing of electrical components and inexpensive fabrication.

Thin Film Resistors: Excellent accuracy, strength, and the lower temperature index of resistance are attributes associated with these widely accepted resistors. Uses requiring great accuracy, including communications, aircraft, and healthcare equipment, are common uses of these PCB types.

Thick Film Resistors: The durability and affordability of thick film resistors make them increasingly popular. A vast range of electronic devices, such as power supplies, sensors, and automobile electronics, can be equipped with them.

Chip Resistors: Such resistors are intended to be small and to function well enough. Chip resistors are widely used in many types of electrical equipment, particularly in electronics for consumers such as laptops, cell phones, and other gadgets where space is a core consideration.

Network Resistors: This PCB resistor reduces space consumption and offers circuit layout versatility by combining several resistive components into a single unit. These are helpful in sectors like data collection infrastructure, precision instruments, and signal processing, wherein multiple resistors are needed

Variable Resistors: Such resistors are perfect for variable resistance since they can be manually adjusted. Examples of these uses include calibrating testing instruments, radio tuning circuitry, and volume adjustments in audio systems.

Through-Hole Resistors: Applications requiring greater power management abilities or requiring an increasingly durable mechanical link with the circuit board are better served by through-hole resistors. These are frequently used in complex electrical systems or where manual assembling is more practical.

Designing A PCB Resistor

Designing a PCB Resistor requires careful layout planning, choosing appropriate materials, appropriate placement of the elements, and precision in manufacturing. The process is quite intricate and requires expertise of the designers to be accomplished. The following are the processes involved in designing a PCB resistor.

Choosing the Right Type of Resistor: The demands of the purpose should determine what kind of resistor to use. Some variables are space limitations, stability, energy ranking, and endurance. Examine which type of resistor might work better for the circuit layout by assessing these factors and other usage specifications.

Calculation of Resistor Value: Calculate how much resistance the electrical system needs. Ensure that the resistor values fit with the circuit’s needs for performance by considering the degree of tolerance and accuracy required.

Taking Tolerance Into Account: The permitted departure from the stated resistance level is established by resistor tolerances. Resistors should be chosen such that their tolerances meet the circuit’s required precision. More robust tolerance resistors are better suited for precision purposes like instrumentation.

Power Level: Choose resistors whose power ratings suit the circuit’s design. Determine the resistor’s maximum energy discharge capacity to make sure it can withstand the anticipated energy without overheating or being damaged.

Temperature Coefficients: A resistor’s resistivity fluctuates with temperatures, and the temperature-dependent resistance ratio shows this. Reduce variations in temperature for applications that are sensitive by using resistors that have a low TCR.

Organization and Positioning: Ascertain where on the printed circuit board the resistors are physically located. To minimize disturbance and maximize heat release, ensure that components are spaced appropriately apart. To reduce the effects of bugs, adhere to suggested style rules while keeping traces brief.

Testing and Validation: Determine the resistance levels and how they affect the circuit’s efficiency by running simulations or building samples after creating the PCB design. When measuring resistance levels, make sure they align with the desired design using multimeters and other inspection tools.

How to Choose the Right Resistor?

Choosing the appropriate resistor for your PCB design can be challenging due to the variety of options available. To navigate this process effectively, it is crucial to understand the type of resistor required. Here are three steps to guide you through the selection process:

- Determine the Required Resistance

Apply Ohm’s law to calculate the resistance needed. Familiarize yourself with the following formulas:

– \(V = IR\)

– \(R = V/I\)

– \(I = V/R\)

Where:

– \(V\) is voltage

– \(R\) is resistance

– \(I\) is current

- Determine the Required Power

Understand the power dissipation your chosen resistor will need. Utilize the formula:

\[P = \frac{V^2}{R}\]

Where:

– \(V^2\) is the voltage squared

– \(P\) is power in Watts

– \(R\) is resistance

- Selecting the Resistor

Once you have the power rating and resistance values, proceed to choose the ideal resistor from an electronic component distributor. Opt for standard resistor types to ensure the longevity of your PCB board.

By following these steps, you can make informed decisions and enhance the overall performance of your PCB design.

Conclusion

Designing and manufacturing a PCB resistor is critical as it can define how well the PCBs function within the gadgets they are placed into. The overall functionality and efficiency of products are impacted by these resistors, making it vital to be vigilant in designing them.