Exploring the Facts of PCB Printing Services

What is PCB Printing Service?

PCB printing services are expert production and creation services that create printed circuit boards with unique designs per predetermined specifications. These solutions include printing conductive lines on insulation surfaces, among other methods, to produce printed circuit boards (PCBs). Various alternatives, including single-layer, double-layer, and multilayer circuit boards, are usually available through these printing service providers. Other services like assembling, examination, and quality control may also be included. These solutions are vital for the electronic sector since they offer a fast and effective method for creating custom electrical circuits.

Purposes Served by Printed Circuit Board Printing Services

Personalization: Printed circuit boards may be customized using PCB printing facilities by certain layout specifications. Customization is necessary for various applications in electronics and electrical devices to have their specific demands met.

Electrical Interconnection: Printed circuit boards are primarily used to create a framework for electrically connecting electronic components. Circuit board printing services guarantee that conductive tracks are placed accurately to develop dependable and effective electric routes.

Tight Integration: Parts for electronics may be integrated compactly using plastic circuit boards. Printed circuit boards enable the development of small and space-saving electronic devices by etching conductive paths on insulating surfaces.

Integrity of Signals: Through careful conceptualization and production of the conductive tracks, PCB printing services help to preserve signal quality. Ensuring there is no loss or even interference of quality when transmitting electrical signals is vital, which these services facilitate.

Guarantee of Quality: Inspection and quality control procedures are often incorporated into the services offered by expert PCB printing providers. These services guarantee that the printed circuit boards follow design criteria, comply with regulatory requirements, and go through evaluation to confirm dependability and functioning.

Time Management: The production method is streamlined by circuit board printing companies, which shortens the time needed to create customized printed circuit boards. This productivity is essential to satisfy strict manufacturing deadlines and launch electronic goods swiftly.

Development and Manufacturing: The creation of prototypes and the large-scale manufacturing of electrical devices are supported by PCB printing solutions. By allowing for evaluation and layout refinement before large-scale manufacturing, designing prototypes lowers the possibility of mistakes and improves the finished product.

Cost Efficiency at Scaling: Large-scale manufacturing might benefit from savings of scale provided by the printed circuit board printing services. It is more economical for producers since it is possible to build numerous printed circuit boards simultaneously, lowering per-unit prices.

Innovative Technologies: Services for circuit board printing use cutting-edge components and manufacturing technologies. This makes it possible to include complicated layouts, innovative capabilities, and many elements in electrical products.

Innovation Assistance: The printed circuit board printing companies foster invention in the electronics industry by offering adaptable solutions. By experimenting with novel ideas, characteristics, and configurations, designers and technologists can test the limits of electronic gadget creation.

Range of Services Offered By PCB Printing Services

Advice for Designing: To help customers improve and optimize their printed circuit board layouts, experienced PCB companies usually offer design consultations. This could involve looking at layouts, suggesting changes to the layout, and making sure the final product complies with the industry’s requirements.

Selecting the Materials: Service providers excelling in PCB printing often offer solutions to assist customers in selecting suitable materials to create their printed circuit boards. Choosing the backing substance, copper thickness, and extra layers to satisfy an application’s particular needs falls under this category.

Implementation of Sophisticated Characteristics: High-frequency circuits, regulated resistance, hidden or concealed channels, and other sophisticated characteristics may be implemented via the printed circuit board printing companies. The circuit boards run more effectively and perform smoother because of these qualities.

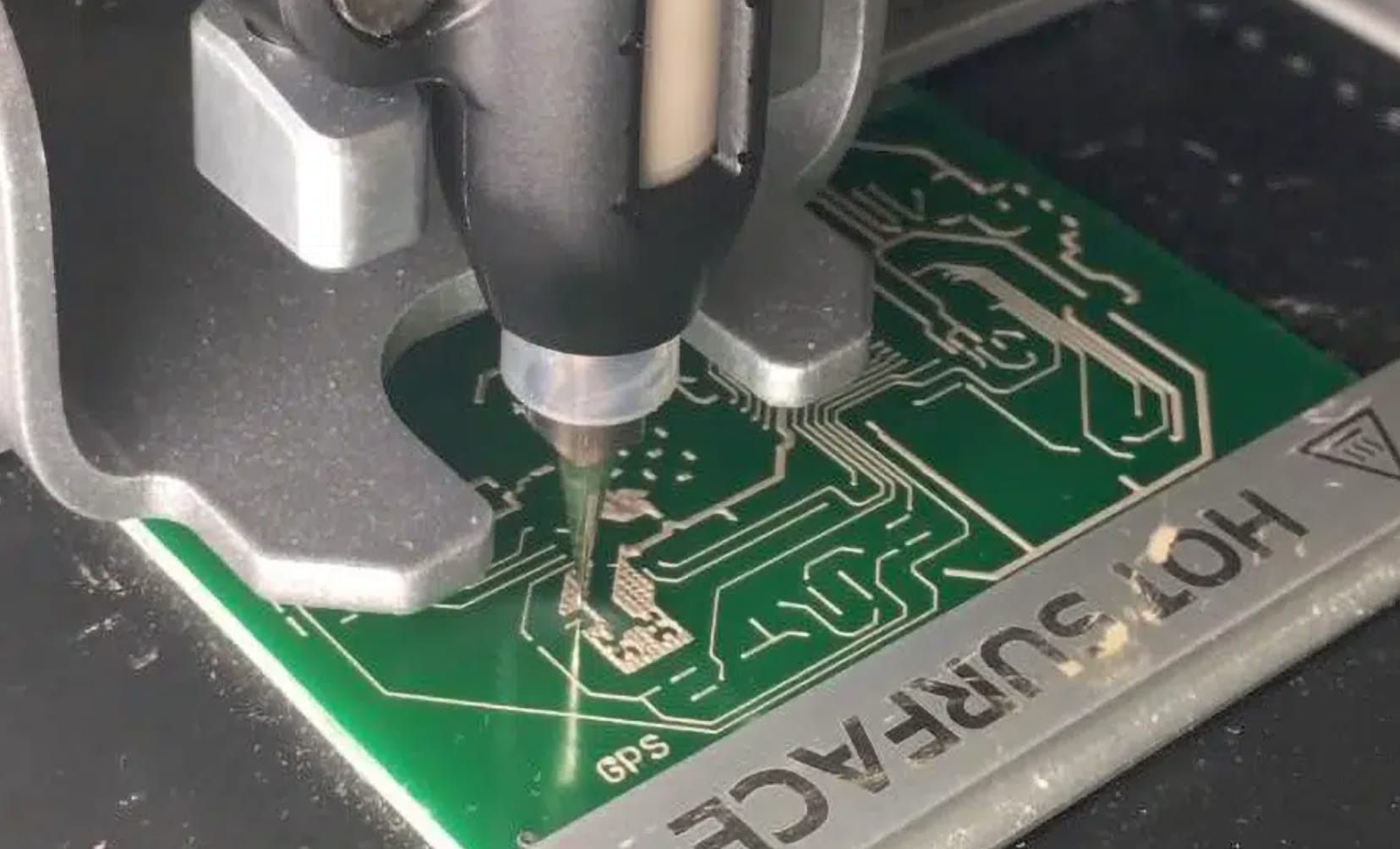

Converting Schematics to PCBs: PCB printing companies convert Conceptual drawings into actual printed circuit boards. Parts, electrical tracks, and various other characteristics can be mapped out by competent technicians or designers using computer-aided design technology.

Production of Multilayer PCBs: According to the design parameters of every project, PCB printing services can create distinct PCBs with varied layer volume requirements. To allow for complicated circuits, multilayer panels entail mounting many different layers of conducting and insulating substances on top of each other.

Manufacturing of Prototypes: Prototype creation and production solutions are often offered by the printed circuit board printing companies for verification and testing needs. Before going into production in large quantities, clients can use prototyping to assess the effectiveness of their designs for circuits.

Surface Coating: Surface polishing procedures are applied to printed circuit boards after the circuit designs are printed. Typical finishing includes applying a soldering mask to safeguard the panel and a surface finish, such as gold plating, to increase conductivity.

Technical Advice and Assistance: Many printed circuit board printing businesses offer continuing technical assistance and direction during the development and manufacturing phases. Customers may overcome challenges, make educated choices, and guarantee the accomplishment of their goals with the aid of these experts.

Assembling Facilities: Placing and attaching the electrical parts to the manufactured printed circuit boards are assembling services that some PCB printing companies provide. This could include Services for mounting parts on the surface or through-hole.

Inspection and Quality Control: Services for printed circuit board printing must include quality control procedures. Thorough testing should be carried out to ensure that the printed circuit boards that are produced fulfill quality requirements and follow the specifications for the design. This testing also includes electric and performance evaluation.

Printed circuit board printing solutions make it easier for electronics manufacturers to enhance the functionality and performance of the devices. Manufacturers can optimize the characteristics by creating customized circuit boards, ensuring the devices run smoother. As such, electronic manufacturers prefer the expertise of PCB printing solutions providers to make the most out of their PCBs.