What is Electronic Manufacturing Services (EMS)?

Have you heard the term electronic manufacturing services but don’t know what it is? Do you want to learn more about the applications of electronic manufacturing? Are you wondering what exactly an electronic manufacturing company does?

Don’t worry! We have collected brief information about all the topics mentioned above. Make sure to read the article till the end and gather all vital information related to electronic manufacturing services.

What is Electronic Manufacturing Services (EMS)?

The term “electronics manufacturing services” (EMS) encompasses both an entire industry and a distinct category of subcontractors or companies. It is frequently used interchangeably with the broader term “contract manufacturing (CM).” In essence, EMS entities offer a diverse array of value-added engineering and manufacturing outsourcing services to original equipment manufacturers (OEMs), enabling them to enhance operational efficiencies and concentrate on core activities such as research and development (R&D).

Electronic manufacturing implicates distinct levels of mechanization. It always relies on the organization and the endeavor. The process is also known as Electronics Contract Manufacture or ECM.

Electronics Manufacturing Industry Market Overview

The research says that few factors influence the electronic manufacturing industry market. These are:

- With time, the need for automotive devices is increasing, and so is the demand.

- Customers are mandating electronic devices, hundred times more than before.

- Emphasis on progressive aptitudes and essential mastery – companies are looking for solution providers that deliver expertise in their specific field or market segment.

- Expansion of mobile equipment – (The market for Android devices, iPhones, and wearable technology continues to grow). “By 2020, 5.4 billion people worldwide will have a phone,” Cisco said in its annual report on mobile traffic.

Electronics Manufacturing Applications

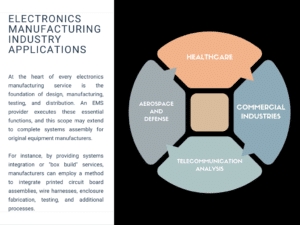

The applications of Electronic manufacturing are seen in many renowned sectors, including healthcare, telecommunication, etc. Some of the best applications of Electronic manufacturing services are discussed below.

Healthcare: Medical and healthcare equipment is one segment of the commercial market that requires steadfastness and dense circuitry. Therefore, involving a good Electronics Contract Manufacture demands significance for getting quality products within budget. In this case, the Original Equipment Manufacturer of OME handovers the enormous task to the EMS to get an impressive outcome.

Commercial Industries: Another application of Electronic manufacturing is seen in the commercial sectors. From PCB assembling to cable assembling, from prototyping to assessing, from contract designing to repairing returned products, Electronic manufacturing services cover everything on behalf of the commercial industries.

Aerospace and defense: Highly durable and robust equipment is a must for military and defense groups. All electronic devices must be strong enough to survive in the hazardous situations defense teams face most of the time. Additionally, the aircraft and jet planes must encompass high security and credibility for operational performance. Hence, it is vital to employ an excellent electronic manufacturing company while developing defense and aerospace devices.

Telecommunication: Telecommunication is a comparably complicated process to develop. Therefore, without a competent developing team, formulating a decent telecom system is next to impossible.

These were some examples of Electronic manufacturing applications.

How to Determine the Right Fit and Business Partner?

There is not an easy way to labeling a particular company as the right one for you. It entirely depends on your requirements and personal choice. But, asking few questions can determine the right fit and business partner for you. Let’s have a look at some questions you can request to determine whether the company is the perfect one for you or not.

From when are they working in this field?

This question will enable you to know the experience of the company in the same field. If a company has years of good experience in the industry, you can select it for continuing your journey.

How extensive is their output examining offering?

It is crucial to know about your chosen company’s output testing procedure to avoid any upcoming complications.

Will they take responsibility for my products once the order gets fulfilled?

There is a slight probability of product malfunctioning, damaging, etc., even after prototyping and assessment before delivery. So, it would help if you got cleared whether your selected company will take responsibility and provide the much-needed support and attention to your products in the long run.

Do they have a recent product introduction procedure in place?

While introducing a new product in the market, maintaining an adequate procedure is utterly significant. So, before partnering with an Electronics Contract Manufacture company, you must get cleared with this query.

Do they offer product lifecycle surveillance?

A decent electronic manufacturer organization must include product lifecycle surveillance in its list. They must supervise the product along with every single element that gets used while developing the final product. So, before finalizing a company, you must ask them this question.

What does an electronic manufacturing services company do?

The works of an Electronic manufacturing services company are widespread. From designing to repairing damaged products, an EMS company covers all. They perform all necessary chores to develop a solid and compatible electronic device. Additionally, the companies always try to stand tall from the competitors in the field and provide quality products each time.

However, an electronic manufacturing services company can be distinct from another, yet they share few similarities. There are some services for almost every Electronic manufacturing services company offers. These are:

- PCB assembly

- Cable assembly

- Electromechanical assembly

- Contract design

- Assessing

- Prototyping

- Aftermarket services

Now, let’s have a look at what an EMS manufacturing services company does.

PCB assembly: Being the most valuable part of an electronic device, designing and assembling a PCB or printed circuit board always need a unique contemplation. In this process, the PCB board gets assembled using either the surface mount strategy or solder component technique. The essential elements such as resistors, transistors, IC or integrated circuits, etc., get connected to a bare board in this stage. Once it gets done, you can connect the actual device with electricity.

Comparing to the through-hole strategy, the first one is easier and progressive. In the last few years, most EMS Electronic manufacturing services companies have been using the surface-mount technique for PCB assembly.

Cable assembly: The next step is cable compiling. It is done by hand soldering, and the company must be authorized for it. So, always choose the right company only after seeing their certificate.

Over modeling is a unique capacity offers by several Electronic manufacturing services companies. It means a tiny part gets developed using various layers and components. Among them, the first one must be coated with more than one element while creating.

Once the cable brings to an end, it is time to examine its capacities. These tests include the hipot test, automatic cable test, etc.

Electromechanical assembly: In this stage, a manufacturer uses various materials and develops various outputs such as box builds. Most manufacturers use steel, plastic, and aluminum in this stage.

An organization can also pack clients’ orders, test the functionality of developed parts, encapsulate and design potting and heat shrink, etc., in this stage. Potting is how organizations use a slimy blend of elements for increasing precipitation, resistance capability, tremor, etc. Furthermore, the cable gets coated with an additional plastic layer for protection in the heat shrink method.

The Electronic manufacturing services companies must be careful while performing electromechanical assembly and should be safe.

Contract design: Contract designing is an essential part of EMS Electronic Manufacturing Services that helps continue the entire process with ease.

A good EMS company always gets engaged from the beginning of the process, even before the product layout gets ready. Electronic manufacturing organizations comprise architects, stock administrators, and several significant staff for executing the contract design via:

- Circuit simulation and prototyping

- Experimenting

- Fixing price

- 3-D CAD and bodily sculpturing

- Technological feasibility reviews

- Integrity survey

These are the fundamental contract designing methods most ems manufacturing organizations follow. If you have problems with the budget, you can visit multiple Electronic manufacturing services companies and negotiate the price.

Assessing: Before shipping the final product to the customer, it is crucial to assess the quality of the element. If an electronic device fails to provide the expected performance, it may cause:

- Impede run time

- Charges additional fees for repairing problems

- It can be risky for your organization’s overall status

A massive number of EMS Electronic manufacturing services companies run tests, including:

- Flowing probe assessment

- In-circuit testing or ICT

- Burn-in testing

- Automated optical inspection or AOI

- Other functional assessments

Prototyping: Once the previous steps get done, it is time for PCB prototyping. This one crucial step can benefit the organizations to avoid upcoming hazards in the future related to the performance of the circuit board.

The prototyping gets done to evaluate things such as:

- Layout drawback inspection

- Stability test of the final product

- Conserving the expense

- Confirming the output

- Inspecting output traits

Prototyping always ensures engineers have a better understanding of how the final product will look in the market. During prototyping, lots of manufacturers concentrate on layout experimentation. It is way more budget-friendly and hassle-free than developing thousands of disputed PCBs.

Aftermarket services: Order shipment is not the end of the ems manufacturing services. After supplying quality products, there is a high that the products can get damaged in the future. Therefore, the companies always have to be ready with their aftermarket policies. It includes:

- Mending returned products

- Renovating

- Calibration

- Promoting

If you want to get your hands into an Electronic manufacturing services company, the first thing you have to assess is whether the organization incorporates competent staff members or not. Secondly, make sure to select a company that fits perfectly according to your requirements and criteria. For instance, if you are looking for a company for telecommunication purposes, choose the company that is certified for providing telecommunication services, not healthcare services.

Why choose us for Electronic Manufacturing?

When you understand what an electronic manufacturing company, especially in the EMS industry, does, it’s time to contact one that aligns with your specific requirements. As professionals in this field, we boast years of experience in manufacturing, assembling, testing, prototyping, and addressing issues related to damaged or returned products.

With us, you can consistently access cost-effective services without compromising on product quality. If you’re interested in exploring what the EMS industry has to offer, make sure to get in touch with us. For those still harboring doubts, contact us as soon as possible to resolve any uncertainties or queries.