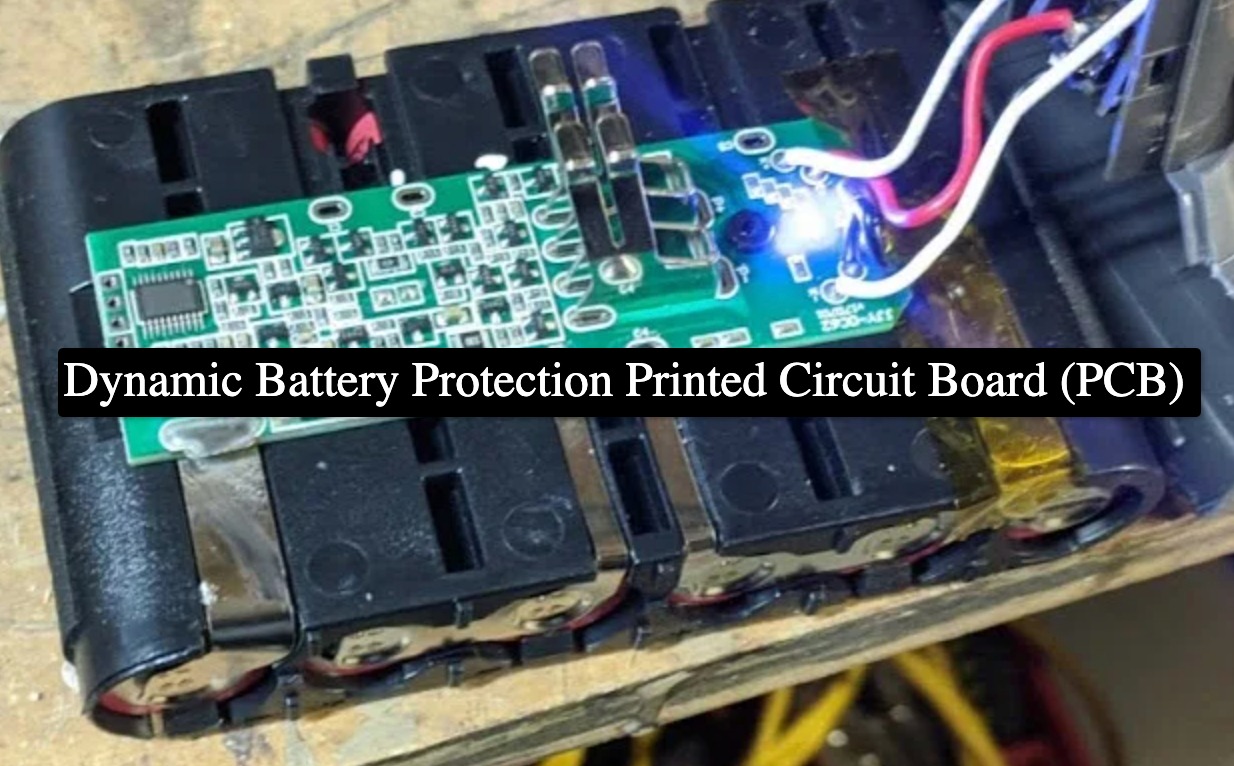

Dynamic Battery Protection Printed Circuit Board (PCB)

The Battery Protection Circuit Board is commonly referred to as the PCB. Battery usage and demand both increase over time as technology advances quickly. All technological devices typically contain batteries. They can be found in various devices, from tiny earbuds to fast electric cars. As a result, a thorough understanding of the battery management system is essential to understand PCBs.

The battery is monitored by the PCB battery management system. Additionally, it balances the batteries’ internal operating parameters. While the battery is being discharged and charged, the characteristics include temperature, voltage, and current. The charging state can be determined with the use of PCB battery management. Knowing the batteries’ health status is also helpful.

Additionally, it contributes to the safety and performance of the battery. Power batteries are in large battery packs. They prevent over-current, over-discharge, and over-charging in the battery packs. Battery packs that have cell stabilization and short circuit protection become regulated. All of these safeguards function while the batteries are being charged.

Importance of PCB Battery Management

The technological and electrical industries benefit greatly from PCB battery management. Its importance extends to every device created by the electrical industry. These devices need to be powered by a battery in order to function properly. However, if the battery’s level of durability is compromised, end users might become dissatisfied.

Batteries are ideal for powering PCBs, devices, and circuits of many types. The system for managing PCBs depends on their functional safety. The system acts as a supervisor during the battery’s charging and discharging processes. During the process, it stops the voltage & temperature of the cells from going over their safe working area limitations.

These area restrictions should only be exceeded when necessary. The battery packs may become damaged if they are exposed to heat conditions continuously for a while. The PCB battery management system also checks the batteries’ lower voltage restrictions. It aids in preserving lithium-ion batteries’ operational safety.

PCM vs. BMS differences

Battery protection packs are classified into two types. The Protection Circuit Module (PCM), also known as the Protection Circuit Board (PCB), is the first category. The Battery Management System (BMS) is the second category. A variety of devices supports batteries in addition to PCM. The Battery Management System is another option (BMS).

These battery protection systems differ in the following ways, except in the size of the battery pack they control:

Hardware Elements: Integrated circuits, MOS tubes, capacitive & resistive components, and MOS tubes are all found on protection circuit boards. A BMS is more sophisticated since it has an intelligent microcontroller that serves as the system’s brain and is integrated with intelligent software.

Precision: A circuit protection module cannot accurately determine the battery pack’s charge level. A BMS, on the other hand, evaluates, monitors, and interprets many measurements, including the health and charge level of the battery.

Steering: PCBs cannot control charging or consuming devices. However, a BMS has communication buses for MODBUS, I2C, and CAN that let it control these devices. The battery usage and system behavior can be optimized thanks to this steering. Electric motors are a common consuming part that the BMS controls.

Low-Temperature Operation: BMSs are unstable at low temperatures even if they have more functionality and perform better than PCBs.

How a PCB Battery Safeguards the Battery

The electrons flow to the anode and cathode when a lithium-ion battery is being charged or discharged. To prevent overcharging, the PCB battery restricts the battery’s voltage while recharging to no more than 4.25V. It may overcharge in the cases listed below.

- Collapsing anode structure

- Short-circuiting

- Internal temperatures rising

- Hard crystal formation

- Fire

Overcurrents will also raise the temperature, which will start fires. Additionally, over-discharging is harmful. It may result in the battery’s capacity ratio being permanently lost. Lithium-ion batteries typically have the lowest voltage of 2.7V, but excessive discharging can drop this value and permanently harm the battery.

Function for PCB Battery Equilibrium Protection

The equilibrium protection function of the protection board has two operational modes.

Energy Balance during Conversion

A large-capacity circuit board battery is switched to a smaller one in this equilibrium (in energy storage terms). The goal of this function is to identify the equilibrium in battery capacity. It is subdivided into fixed-point and constant capacity balance.

Balancing Energy Consumption

There are three categories for balancing energy use.

- Equilibrium charging: The circuit board starts equilibrium protection if the voltage of any battery cell exceeds the average voltage of the battery when it is charging.

- Equilibrium of fixed-point voltage: The charge management board is configured to begin balancing at a defined voltage point after charging the batteries. And with a shorter acclimatization period.

- Automatic static balancing: Even when the battery is in a static store state, this equilibrium is maintained while charging and discharging. The battery PCB will activate equilibrium protection to stabilize the voltage if it is irregular.

The Battery Protection System of a Standard Lithium Battery

The chemical properties of lithium batteries induce internal chemical reactions. These chemical and electrical energy conversion processes take place. The internal battery may overcharge, over-discharge, or overcurrent in certain circumstances. The chemicals also have certain unintended adverse effects on us.

The battery’s performance and longevity are both negatively impacted by these interactions. They might produce large volumes of gas, which could raise the battery’s pressure and occasionally result in an explosion. It might lead to a few security issues.

Because of this, a protection circuit is necessary for all lithium batteries. The circuit performs an excellent job of keeping an eye on the circuit board battery while it is being charged and discharged. The circuit interrupts the charging or discharging when undesirable side effects arise to protect the battery from harm.

PCB-boarded portable chargers

Power banks PCB stands for a portable lithium battery. It has a converter PCB inside because it cannot directly charge a phone by itself. The charge and voltage are converted. Many goods produce more PCBs (Printed Circuit Boards). The PCBs contain an IC and additional parts that ensure the circuit’s completion.

The PCBs significantly influence a power bank’s ability to operate. It increases the power bank’s battery voltage to match the voltage needed to charge an electronic item. A decent power bank also features a circuit board protected from short circuits, charge and discharge surges, and safety circuits.

A PCB that allows for more charging and longevity is an indication of a high-quality power bank. Work determines the power bank’s input and output quality. It can be difficult to tell which power banks have a benefit in terms of appearance due to the large number of options available.

The 18650 PCB Battery

A lithium battery with a safety circuit board is the 18650 PCB. The protection circuit board aids the battery’s safety. Depending on the battery type, each protection board functions differently. They all serve a similar purpose to safeguard the battery from short circuits, overcurrents, over-discharging, and overcharging.

The protection circuit board performs crucial functions in maximizing the 18650 PCB battery’s level of security, toughness, and performance. The safety circuit board system safeguards the battery’s cells during charging and draining.

The 18650 PCB is an effective battery type used in products like flashlights, computer battery packs, wireless devices, and other equipment that requires a reliable power source. In addition, there are two varieties of 18650 PCBs: protected and unprotected.

Conclusion

The circuit board battery management system is essential for the battery to remain reliable, effective, and safe. Small digital batteries must be protected from overcharging, over-discharging, short circuits, and over-current with PCB batteries. These little batteries are frequently used in portable devices; therefore, they only require a minimal hardware protection mechanism to fit inside the devices.