What Are Conformal Coatings? Everything you need to know

Due to technological advancements, there is increasing use of electronics for different purposes. However, some electronic connections are highly sensitive to dust, moisture, and temperature. These factors can damage different components and affect the overall integrity of the electronic assembly. One of the best ways to prevent this problem is to apply the conformal coating. It refers to the process of applying a thin and transparent coating to the Printed Circuit Board. Thus, this coating has gained high importance to circuit board manufacturers. Learn more about conformal coating and its applications.

What is the conformal coating?

It is a polymer film with thickness ranging from 25 to 75µm. The standard thickness is about 50µm, conforming to the PCB topology. The major purpose of using this protective coating is to save your circuit board from adverse environmental conditions. The fluctuating temperature, high humidity, and air pollutants cannot damage your electronic circuits due to this coating. Thus, conformal coating ensures electrical insulation to keep up Surface Insulation Resistance for a long period. Your electronic assembly will maintain its operational integrity due to the special coating. The coating creates a barrier to salt-spray and other contaminants to prevent rust.

The polymeric resin present in the coatings may include more than one solvent for the materials’ proper dispense. However, it is important to choose the best resin to ensure an optimal level of protection for your electronic items. But, the way of applying the coating and ease of rework are some other relevant factors.

Conformal coatings are semi-permeable and not waterproof in nature. Thus, they do not ensure the perfect sealing of the coated electronics. They make your electronic device highly durable.

Why should you use conformal coatings?

Circuit board coating is valuable to you in different ways.

- As the coating has some insulating properties, it helps in a more than 80% decrease in your circuit board conductor spacing.

- With this coating, you can avoid the use of complicated enclosures.

- The coating is lightweight, and thus, it is easy to apply on your board.

- It ensures 100% protection to your assembly against corrosive and chemical attacks.

- The coating reduces the chance of any negative effect on the PCB’s performance for environmental conditions.

- Your PCB assembly will have reduced stress caused by environmental issues.

Some electronics may not depend on the surrounding environmental conditions. However, most of them are sensitive and need high durability. For instance, IPC class 3 devices must have this coating because they have a mission-critical nature. As there is a trend of manufacturing wearable gadgets and miniaturizing electronic devices, better protection has become important. That is why the conformal coating has started gaining high popularity in recent years.

Industries that need conformal coatings–

In the past, the circuit boards intended for mission-critical applications (such as aerospace) need conformal coating. However, this coating is now useful in different industries, like-

- Military

- Automotive

- Lighting

- Marine

- Mobile and domestic electronics

- Green energy and industrial applications

The use of conformal coating ensures high reliability and good performance of electronic devices.

How do you select conformal coating? Find the best practices–

You may think it to be easy to choose conformal coating based on your budget. However, the most important thing for you is to achieve the proper protection level with the coating material. Thus, the choice of the best material is essential to get the desired result. Coatings are of different types, and you need to identify one, which performs at the optimal level in the operating environment. Thus, you need to focus on different factors to select the right conformal coating. A brief outline of different conformal coatings will help you to make a decision.

Based on the chemical composition, you can categorize conformal coatings in different ways. Each of the types of coatings has some beneficial properties. In most cases, they have solvent-based materials that ensure-

- Tailored application

- Easy processing and viscosity adjustment

- High suitability for different application processes

Types of conformal coating PCB.

Acrylic coatings–

Available at an affordable price, these coatings ensure the best environmental protection. Moreover, they resist hydrolysis and darkening issues while maintaining a high level of clarity. These coatings contain acrylic polymers dissoluble in solvents. The solvent-resistant capacity is limited, and thus, you can choose the coating for reworking purposes. Besides, when you need high chemical resistance, you may rely on acrylic coatings. To sum up, acrylic coatings are best for-

- Comprehensive protection and high versatility

- Easy application and removal

- The capacity of drying quickly under normal temperature level

- Capable of working under a wide range of operating temperature

- Potential to adhere to different substrates

One of the demerits of acrylic coatings is that they have low-abrasion resistance.

Silicone coatings–

They are highly temperature-resistant coatings ensuring a high level of protection in different environments. But, these coatings are not resistant to corrosive gases and humidity. The best feature is that it is easy to process these coatings containing single-component compounds.

Moreover, silicone coatings are resistant to chemicals and adhere to your PCB components. However, one disadvantage with these coatings is that you cannot remove them easily. You may need strong chemical strippers for the successful removal of coatings.

Polyurethane Coating

Polyurethane coatings are better than acrylics, and they have high chemical resistance capacity. Moreover, they can protect your board from adverse environmental conditions. Besides, their capacity to work under a broad range of temperatures proves their versatility.

Hybrid Coating

The term hybrid indicates that this coating has a blend of different chemistries. That is why you will get a range of coating options for diverse applications.

For instance, conformal coatings may have silicone-modified polyurethane base resins to augment their high-temperature endurance properties. These coatings are more advantageous than standard materials. Due to their solvent-based nature, they are easy to apply on the circuit board. On the contrary, regular silicone coatings have effects of siloxanes with low molecular weight.

When you need some reworking effort, you have to use specialist coating removers.

Parylene coatings

You can apply these coatings through a special process known as chemical vapor deposition. While heated, Parylene gets converted into gas. After cooling it, you can put it into vacuum chambers for polymerization and transform it into a coating. Apply this coating over your electronics.

The best feature of Parylene coatings is high dielectric strength, colorless, and transparent. Moreover, there is no curing time needed for these coatings.

Water-Based conformal coating

You can cure this water-based coating with the evaporation method. It has a minimal level of VOC and replaces most of the solvents with water. It ensures safety to the operator and decreases the solvent emission level. That is why it is also safe for the environment. Moreover, high chemical resistance is another notable trait of this coating. You can use standard equipment to apply this coating.

2K Coatings

Manufactured with hybrid technologies, these coatings consist of two parts. They combine the best encapsulation properties of resins to provide you with a high-quality conformal coating. The blended materials ensure ultimate protection while retaining the processing potentials and affordability of your coating.

2K coating is a high-performance solution protecting your circuit board from environmental issues. You can apply thick coatings that protect your board from moisture.

UV Cure Coating

It is one of the best hybrid coatings for your PCB. You will find different types of chemistries to provide you with a dual-core system. You may not find problems with parts that do not get UV light for curing. This coating gets cured within the shortest time, and thus, you may choose it for your high throughput applications.

How should you apply your conformal coating?

Before dealing with the conformal coating process, you have to check out some factors

- Production throughput– You need some preparatory steps to make the coating process faster.

- Board design– The presence of solvent-sensitive connectors, components, and some other variables will have an impact on the process.

- Equipment– While you need coating sporadically, you may avoid using costly and specialized equipment.

- Pre-coating– It is about taping and masking prior to the application of coating.

There are different methods for applying conformal coatings.

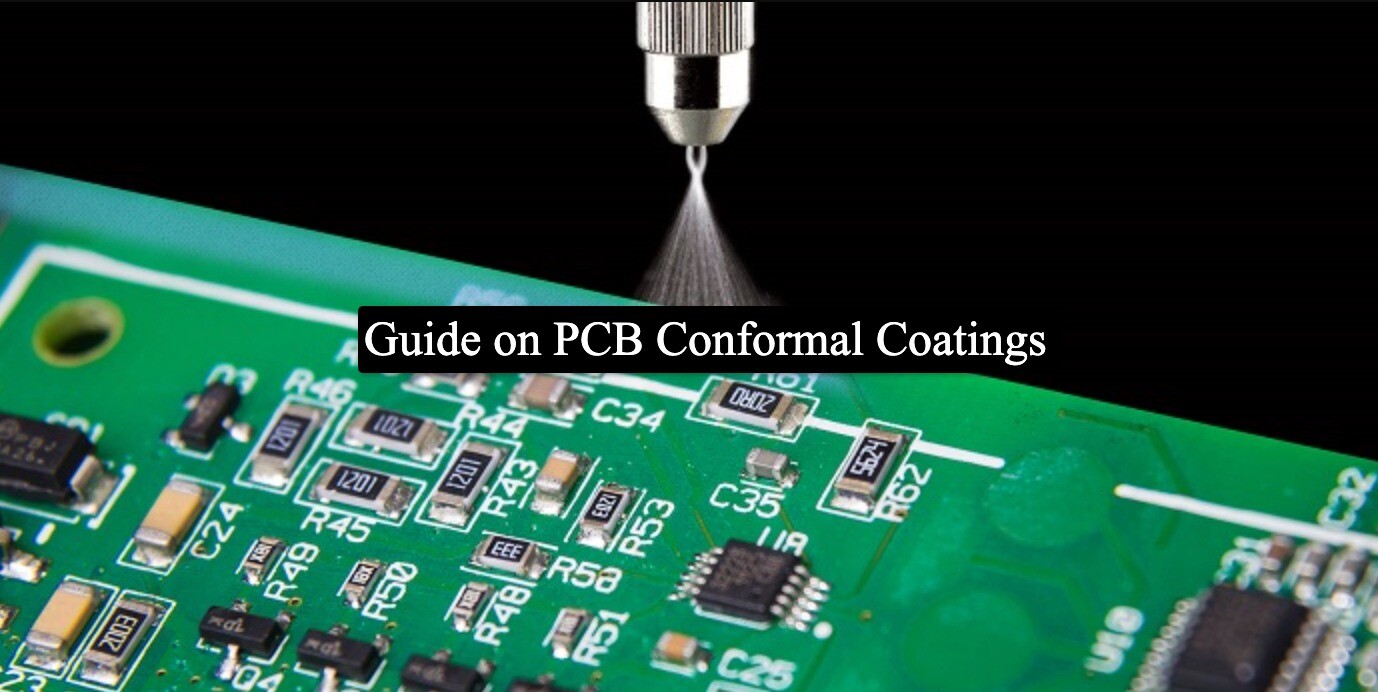

- Automated spraying – As the spray system is programmable, it moves your circuit board on the conveyor.

- Manual spraying– You do not need highly complicated equipment for a low quantity of production. You may apply the coating using a spray gun and aerosol gun. However, it is a time-consuming process, and you can find differences in every board.

- Selective coating – You have to use an innovative and automated spraying system that presents you with a specialized nozzle for the application of a conformal coating to the PCB. You can avoid the masking process with this coating method.

- Brushing – You can rely on this method for reworking and repairing purposes. Apply the coating on your board using the brushing method. Moreover, to get a cost-effective solution, you may prefer this method.

- Dipping – It is one of the most acceptable ways of applying the conformal coating. Masking is essential before coating your PCBs. When you need to coat two sides of your circuit board, you can choose the dipping method. Factors affecting the creation of film are the withdrawal speed, immersion speed, and immersion time.

Measuring the conformal coating’s thickness–

Micrometre– You have to take measurements on different parts of the PCB before and after applying the coating. After curing the coating, you need to subtract the thickness from the uncoated thickness. You will get highly accurate measurements for your hard coatings.

Current probes– It is a test probe for direct measurement of the coating’s thickness. The system creates an oscillating electromagnetic field for the measurement. The non-destructive thickness measurements are accurate.

Ultrasonic gauge – It checks coating thickness with the use of ultrasonic waves. That is why there is no need to use a metal backplane. The time taken by the sound waves to pass through your coating gives the result.

How should you cure conformal coatings?

You need to know about different curing processes-

- Evaporative cure– The evaporation of the liquid carrier can leave the resin as residue. You can combine this process with a moisture cure mechanism. PCBs are reusable within one hour.

- Moisture cure– The coating will react with moisture and produce a polymer coating. The full curing can take a number of days.

- UV Cure – The ultraviolet light helps in curing your coating, as it does not have a carrier solvent. Thus, you need a secondary mechanism for perfect curing.

- Heat cure– You can use it with multicomponent systems. The application of heat causes polymerization.

Now, it can be concluded that you have to be careful while choosing conformal coating PCB. It is important to protect the board. However, you must use the right material for protecting circuit board coating. You have to consider environmental conditions, repair needs, and other factors.

Also read:-