A Comprehensive Guide to Printed Circuit Board Materials: Types, Properties, and Applications

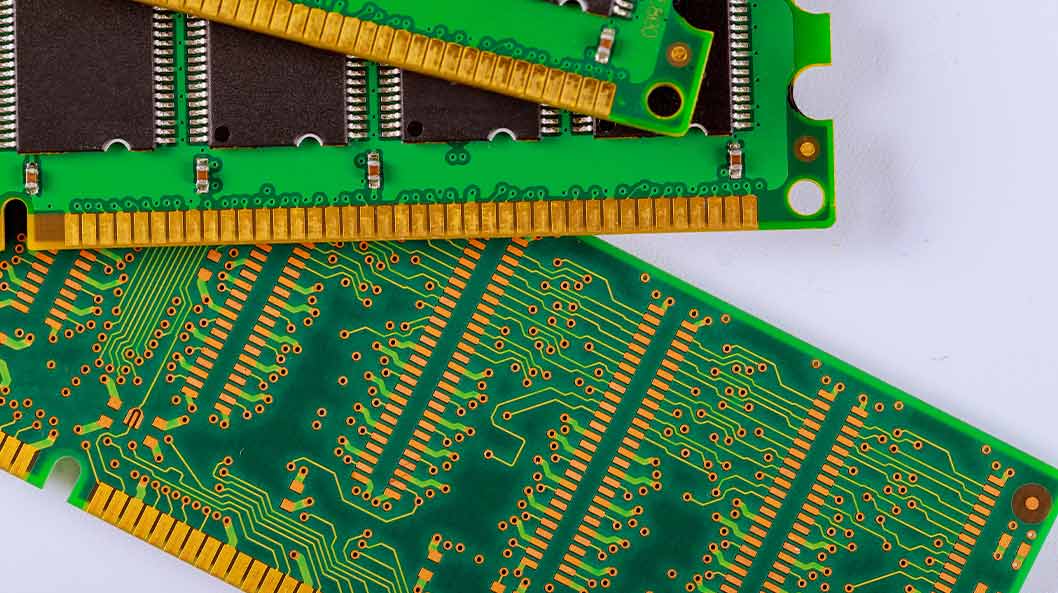

Printed Circuit Boards (PCBs) form the foundational structure for modern electronic devices, providing both mechanical support and electrical connectivity to various components. The performance, reliability, and longevity of a PCB are directly influenced by the properties of its materials. From high-frequency communication systems to industrial-grade machinery, selecting the appropriate printed circuit board materials is a crucial step in ensuring optimal functionality and durability.

Prior to initiating PCB manufacturing, it is imperative to evaluate the types, properties, and applications of various materials. Factors such as thermal stability, dielectric constant, and mechanical strength play a significant role in determining material compatibility with specific designs and operating conditions.

This article provides an in-depth technical overview of PCB material classifications, their key attributes, and applications, serving as a guide for professionals aiming to optimize their electronic assemblies.

Importance of PCB Material Selection in Printed Circuit Board Manufacturing

The selection of PCB materials is a critical factor in the printed circuit board manufacturing process, directly influencing electrical performance, mechanical integrity, and thermal management. Materials dictate the PCB’s ability to operate at the required frequencies, withstand environmental stress, and maintain longevity under varying thermal conditions. Optimizing material selection ensures the board can meet the stringent demands of high-performance applications, from telecommunications to aerospace.

Key material properties such as dielectric constant, thermal conductivity, and coefficient of thermal expansion (CTE) must be meticulously matched with the intended use case. The right material ensures effective signal integrity, minimizes losses, and guarantees reliable power distribution. Additionally, the PCB material’s ability to dissipate heat is essential to prevent overheating, especially in high-power and high-density circuit designs.

- Dielectric constant (Dk) impacts signal transmission speed and impedance control.

- Thermal conductivity (W/mK) is crucial for effective heat dissipation, preventing thermal damage in power-intensive applications.

- Coefficient of thermal expansion (CTE) must match the components and substrates to avoid mechanical stress during temperature fluctuations.

- Glass transition temperature (Tg) indicates the material’s stability and resistance to deformation under heat.

- Low loss tangent reduces signal loss, ensuring efficient performance in high-frequency circuits.

- Mechanical properties such as tensile strength and flexibility are essential for durability and handling in complex PCB designs.

- Material compatibility with soldering processes ensures reliable joints and prevents failures in the manufacturing process.

Different Types of Printed Circuit Board Materials

The selection of materials for Printed Circuit Boards (PCBs) is determined by the electrical, thermal, and mechanical demands of the application. The material’s properties, such as its dielectric constant, loss tangent, thermal conductivity, and mechanical stability, are critical in defining the board’s performance. Below is a detailed classification of commonly used PCB board materials:

1. FR-4 (Epoxy-Fiberglass Laminate)

FR-4 is the most widely used PCB material due to its excellent electrical insulation, mechanical strength, and affordability. Its low dielectric constant (Dk) and high dielectric strength make it suitable for general-purpose electronic devices. FR-4 materials are typically used in PCB manufacturing for multi-layer PCB boards in consumer electronics and industrial equipment.

2. High-Frequency Laminates

High-frequency laminates, such as PTFE (Polytetrafluoroethylene) or ceramic-filled materials, are engineered for applications requiring minimal signal loss and precise impedance control. These materials exhibit low loss tangent and stable dielectric constants, making them indispensable for RF and microwave systems, including telecommunications and aerospace electronics. High-frequency printed circuit board materials are critical for advanced PCB prototypes and production runs.

3. Metal-Core PCBs (MCPCBs)

Metal-core materials, typically composed of aluminum or copper, are designed to provide superior thermal management. The metal core efficiently dissipates heat, making these materials ideal for high-power applications such as LED lighting, power converters, and automotive electronics. These PCB board materials are widely used by printed circuit board manufacturers due to their reliability in thermal-sensitive environments.

4. Flexible PCB Materials

Flexible PCBs use substrates like polyimide or polyester, allowing the board to bend or fold without compromising performance. These materials exhibit excellent thermal and chemical resistance, making them suitable for compact designs such as wearables, medical devices, and flexible displays. Flex materials are common in printing circuit boards for consumer electronics.

5. Rigid-Flex Materials

Rigid-flex materials combine the mechanical robustness of rigid boards with the adaptability of flexible substrates. These PCB board materials are used in complex assemblies where space and weight are critical factors, such as aerospace and defense electronics. They are a popular choice for printed circuit board prototypes during product development.

6. Ceramic-Based Materials

Ceramic-based PCB materials, including alumina and aluminum nitride, are employed in high-performance applications requiring superior thermal conductivity and minimal electrical losses. They are often used in high-frequency and high-power devices, including RF amplifiers and power electronics. These PCB board components are known for their excellent thermal properties.

7. Composite Materials

Composite laminates combine different materials, such as woven fiberglass with resin systems, to achieve a balance of mechanical strength, thermal stability, and electrical performance. These materials are frequently used in advanced multilayer printed circuit board materials for aerospace, automotive, and industrial applications.

The choice of PCB circuit board material impacts on the electrical characteristics of the board and its manufacturability and long-term reliability. Understanding these materials’ distinct properties ensures optimized design and operational efficiency for specific industry requirements.

Applications of Printed Circuit Board Materials

The choice of printed circuit board materials significantly impacts the performance, reliability, and durability of electronic systems across various industries. Below, we explore key applications and the role of different PCB materials in each.

1. Consumer Electronics

FR-4 is the most commonly used PCB material in consumer electronics due to its mechanical strength and electrical insulation properties.

- Ideal for high-volume, cost-sensitive applications such as smartphones, laptops, and home appliances.

- Supports multi-layer PCB boards, enabling compact and efficient designs.

- Provides electrical insulation, ensuring stable operation in sensitive electronics.

- Offers good mechanical properties for durable consumer products.

- Cost-effective for large-scale production while maintaining high reliability.

- Widely used in power-sensitive devices for seamless performance in everyday products.

2. Automotive Electronics

Metal-core PCBs (MCPCBs) are widely used in automotive electronics for efficient thermal management, particularly in power-intensive applications.

- Used in LED lighting, power converters, and engine control units.

- Helps dissipate heat, preventing overheating in automotive systems.

- Ensures reliable performance in electric vehicles and safety systems.

Summing it up

Choosing the perfect PCB material can make all the difference in how your circuit board performs over time. With so many options out there, it can feel overwhelming, but that’s where we can exactly help you!

If you’re unsure about which material is right for your next project, get in touch with our experts – we’ll guide you every step of the way to ensure your PCB is top-notch.