Turn your concept into a reality

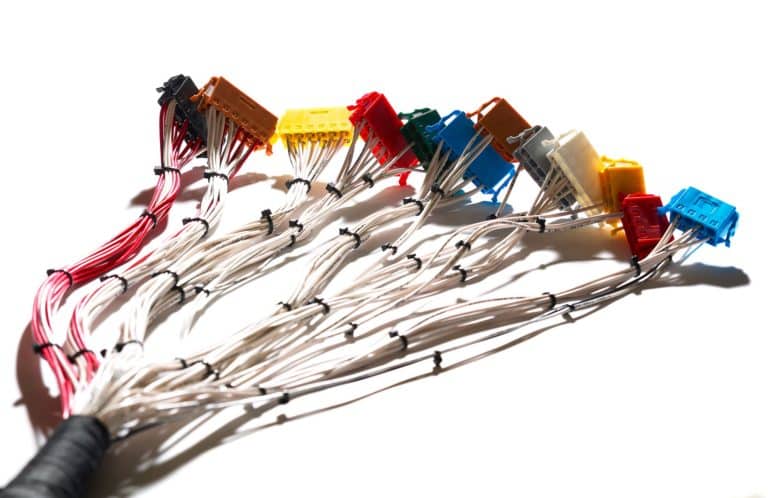

We offer Wire Harness and Cable Assembly services. The first step in a Wire Harness and Cable Assembly process is to cut wires into the proper dimension we require. This process is usually done either by hand or by a machine specially designed for wire cutting. After this step, the core of the wire is exposed and then fitted according to the requirement. In the end wires and cables are assembled in a Wire Harness which involves either an assembly board or a workbench.

Cable and Wire Harness Assembly can be prepared either by machine or by hand. Both the process has different methods to prepare. Generally, they include inserting and routing wires through various sleeves, compress the terminal in wires, using cables ties, etc. As there are many processes involved in the Cable and Wire Harness Assembly process, it is done either by hand or by semi-automatic machinery.

We can help. Our team of expert is on hand to answer your questions

Since 1995, Absolute Electronics Services has been a trusted provider of high-quality Wire Harness Manufacturing solutions across industries like consumer electronics, telecommunications, medical devices, and automotive sectors. We specialize in custom wire harness design and manufacturing for on-/off-road heavy equipment and industrial panels.

Key Advantages:

Wire harness and cable assembly involves bundling electrical wires or cables to transmit power or signals, secured with materials like cable ties, straps, or tape. The process follows the IPC/WHMA-A-620 standard, ensuring quality and reliability across three classes:

Absolute electronics is Rated 5.0 based on 3 reviews.

Selecting the right Wire Harness Cable Assembly is crucial to ensure optimal performance and longevity of electronic equipment. Partnering with experienced manufacturers like Absolute Electronics Services can streamline this process, offering the following key benefits:

At Absolute Electronics Services, we utilize cutting-edge technology and a highly skilled engineering and production team to meet complex wire harness and cable assembly requirements. From prototypes to full-scale production, our engineering team collaborates closely to meet technical specifications and rigorous testing standards.

1. DC Wires: 12V cross-linked polyethylene insulated for automotive and PCB (e.g., GXL, SXL, TXL).

2. AC Wires: UL/CSA listed wires like MTW and THHN (e.g., UL 1015, UL 3173).

3. Wire Sizes: Available in sizes from 4/0, 3/0, 2/0, 1/0, and 1 to 24 gauge.

4. SAE J1939 Twisted Pair: Specialized CAN Bus twisted pair wires.

1. Durability: Compliant with SAE J2202 standards.

2. Inkjet Marking: Available in white and black.

3. Custom Print Spacing: Marking every 3 inches or more.

4. Heat Shrink Printing: Durable, permanent labeling options.

1. Electrified Build Board: 100% continuity testing for assemblies.

2. Test Fixtures: Customized mating harness test fixtures.

3. Comprehensive Testing: Includes continuity, resistance, and hipot testing.

1. Compliance: Adheres to SAE J163 standards.

2. Ultrasonic Welding: Wire sizes from 0.5mm to 40mm.

3. Soldering: Follows SAE J473a guidelines.

4. Crimping: Expertise in butt and parallel splices.

1. High-Temperature Vinyl Coating: Nylon braiding for extreme temperatures.

2. Moisture and Chemical Resistance: Enhanced protection options.

3. Split Loom: Flexible insulation for wire harness protection.

4. Adhesive Taping: Flame-retardant, UL-approved tapes.

5. High Abrasion Resistance: Designed for mechanical durability.

6. Flexible PET Sleeving: Ideal for complex wire routing.

Address :

Absolute Electronics Services LLC

330 W Fay Ave

Addison, IL – 60101

2026 Absolute Electronics Services, All Rights Reserved