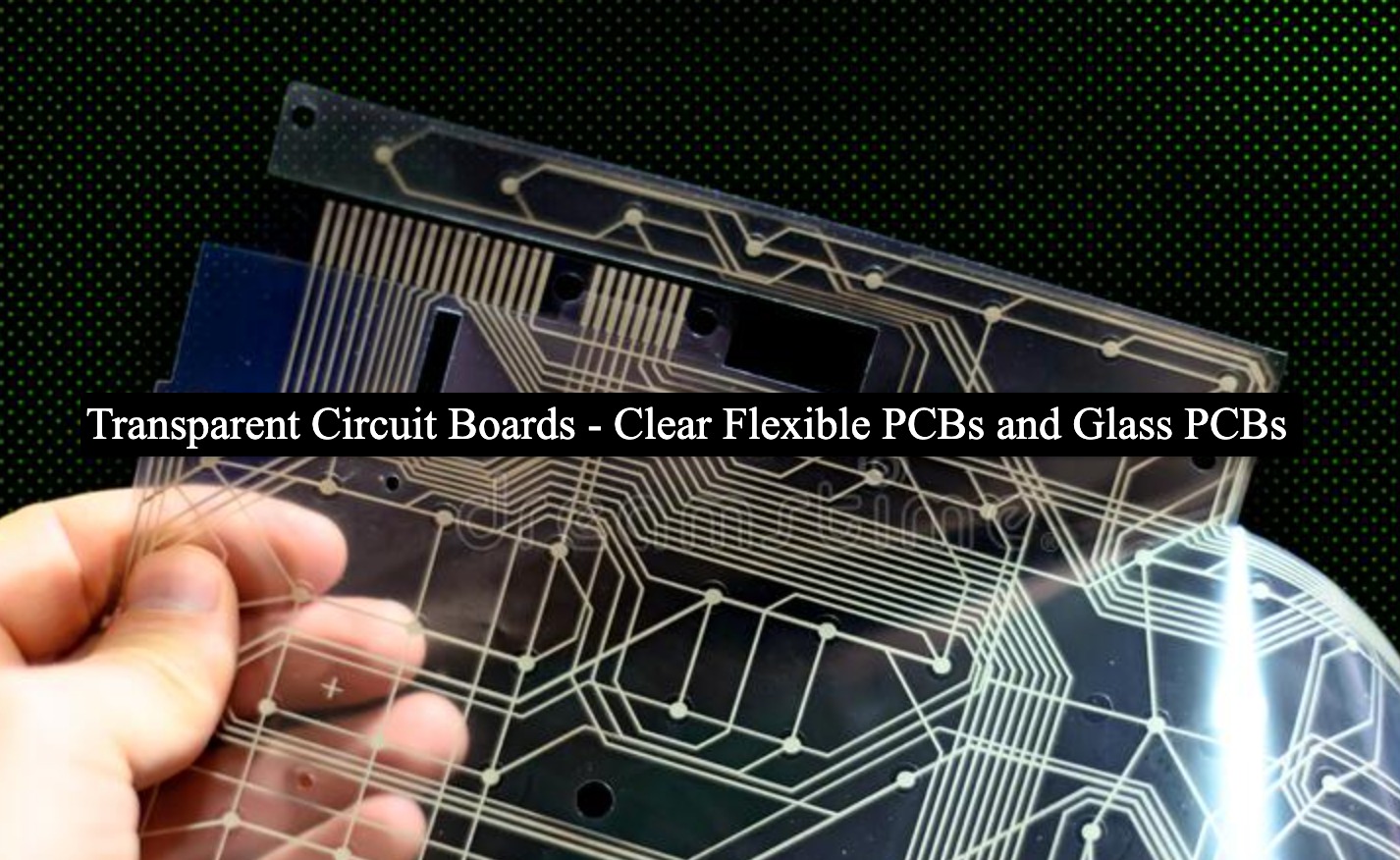

Transparent Circuit Boards – Glass PCBs and Clear Flexible PCBs

Transparent Circuit Boards

The PCB sector is likewise growing quickly to meet the rising demands and specifications of different electronics and electrical equipment. For instance, translucent PCBs, metal OCBs, and ceramic PCBs. In optical areas, the transparent circuit board is crucial. High-tech products, computer hardware, and home appliances all contain electronic circuitry. Even the circuit boards’ electrical lines and integrated components can be transparent, allowing visibility through a transparent PCB. While some transparent circuit boards are ceramic PCBs, the majority of transparent circuit boards can be flexible PCBs made using PET film. A transparent PCB can be seen through, as its name indicates. In addition to the PCBs, the conductive traces and components incorporated in the circuit boards can also be entirely or partially transparent. In this article, we’ll provide you with an introduction to clear, flexible PCBs and transparent glass PCBs.

Transparent Flexible Circuit Boards

Different PCB specifications apply to new electrical and electronic equipment. Flexible PCBs are frequently made using polyamide, PEEK (polyether ether ketone), or a transparent conductive polyester sheet as the substrate. As a result, it is common to see translucent ceramics boards, transparent circuit boards, and aluminum PCBs installed inside them, keeping the idea of a clear board in mind. The market has long featured transparent PCBs.

Flexible PCBs (FPCs) built of PET thin film are transparent. PET materials are available in clear white, light blue, green, and a few different colors. Clear FPCs can only be distinguished from traditional flexible PCBs by using transparent PET materials. In certain transparent flexible PCBs, you can see the electrical traces, and pads are visible. Some transparent flexible PCBs have completely transparent conductive traces. The circuit is secured between two translucent materials using an inventive manufacturing technique, rendering it imperceptible from the outside.

Advantages of transparent flexible PCBs:

The perks of using transparent flexible PCBs are-

- They offer a variety of fantastic optical characteristics.

- They may be bendable, foldable, twistable, and moveable at will, only with a clear board.

- When compared to rigid printed circuit boards with the same volumes, flexible printed circuits reduce product weight by around 90%.

- The manufacturing precision of this transparent PCB is nano- or micrometer-level.

- Ideal for product thinning, downsizing, and weight reduction.

Applications of transparent flexible PCBs

The following is a list of some uses for transparent flexible PCBs:

- In the auto industry, they are used in ABS systems, underbody controls, instrument panels, and under-the-headliner circuits.

- Flexible circuits are used on the printing printhead of printers. They help to link signals to the moving arm of the HDD that carries the read/write head.

- Consumer electronics products, including cameras, telephones, calculators, and training monitors, also include flexible circuitry.

- When several connections must fit into a compact space, flexible circuits are employed in industrial and medical applications.

- Smart lenses and electronic skins use flexible PCBs that are completely transparent and have a clear board.

Technical specifications

- Transparency might be anything between 94.36% and 100%.

- The number of layers on the transparent circuit board might be between one and 10.

- Between 0.1 mm and 0.6 mm is the thickness of the final transparent flex PCB.

- The range of copper thickness is 17.5 mm to 70 mm.

- The surface finish incorporates a variety of ingredients, including immersion tin, immersion silver, ENIG, OSP, and ENEPIG.

- The laser blind hole must be at least 0.075 mm in diameter.

- The mechanical drilling hole must be at least 0.1 mm in diameter.

- The required line width is 0.035 mm.

- Line spacing must be at least 0.035 mm.

- A blind hole can have an aspect ratio as high as 0.8.

- The interlayer alignment must be at least 0.05 mm.

- The heat tolerance for soldering may increase to 260 °C in 5 seconds.

- The required adhesive strength is 490 N/m.

- 300 °C is the maximum temperature at which glass transitions.

- The operating temperature ranges from -25 to +75 degrees Celsius.

Transparent Glass Circuit Boards

Our daily lives are surrounded by printed circuit boards. Glass PCBs include something other than a transparent circuit board, much as other PCB kinds do in this transparent PCB manufacturer world. Ultra-white float glass serves as the substrate for transparent glass PCBs, which have a thermal conductivity of 3.9 W/m2K. To create glass, a mixture of soda, limestone, ash, and sand is used. These materials are also abundant in nature and simple to recycle. Glass is, therefore, a sustainable material. The prestressed glass that has undergone additional processing and prestressing to boost durability is tempered glass. Additionally, it is more effective at absorbing stress and impact, making it excellent for demanding applications. The toughest and longest-lasting glass is sapphire. Due to its superior dielectric and thermal qualities, it is the preferred glass PCB material for high-end electronics and satellite or spacecraft components. Glass-transparent PCBs also features 360-degree luminosity. Light may therefore go in any direction. This is one important reason why it appeals to so many devices. One significant advantage, and possibly the best in its ornamentation, is that it is made of invisible wire. This significantly raises the value of the gadgets.

In addition to transparency, glass PCBs provide the following benefits:

- Substantial thermal conductivity

- Dustproof, moistureproof, and water resistant

- Optimal resistance against corrosion in challenging settings

- Excellent flatness and a small expansion coefficient

- Stunning views and excellent reflectivity

- Can be laminated with metal, PI, PET, high-frequency materials, and hybrid materials.

Applications of transparent glass circuit boards

- It includes solar technology,

- LED displays made of glass,

- New applications for electrical devices, and

- Planes, rockets, etc., have infrared windows.

Technical specifications of transparent alumina circuit boards:

- The range of transparency is 77% to 85.63%

- The air’s U-value ranges from 2.0 W/m2K to 3.9 W/m2K.

- Thermal absorption might reach a maximum of 15% to 33%.

- Thermal reflection ranges from 11% to 14%.

One-Stop Transparent Circuit Boards Manufacturer

Since our inception, we have been providing transparent circuit board fabrication and assembly to customers all over the world. Automotive, defense, industrial, medical, communications, and consumer electronics are among the sectors we service.

Purchasing a transparent circuit board from us will provide you with the following benefits:

- Manufacturization and assembling of transparent PCBs, incorporating glass and clear FPCs, in one location.

- To help you with best practices, the CAM engineer of our organization will offer one-on-one engineering support.

- With the newest technology and manufacturing optimization, you will be able to manage to lower your expenses consistently.

- To make sure transparent circuit board is performing at their peak electrical efficiency, we do functional testing and four-terminal sensing.

- You may get HDI PCBs, rigid-flex PCBs, aluminum PCBs, high-frequency PCBs, regular FPCs, and ceramic PCBs as well from us, in addition to transparent circuit boards.

Conclusion

This blog covered every aspect of transparent circuit boards, including glass and translucent flexible PCBs. Transparent PCBs have significantly impacted the PCB market. The optical industry makes extensive use of transparent PCBs provided by transparent PCB manufacturers around the world. There are abundant transparent circuit board manufacturers available for you to pick from. However, you should do your research and understand your requirements and choose what serves you the best.